Indicator Diagrams

- To enable evaluation of the power developed in each engine cylinder.

- To highlight conditions during fuel injection, combustion and after burning.

- To highlight conditions prevailing in the cylinder during scavenge/exhaust gas exchange process.

- To show the pressure variation in the cylinder with respect to piston displacement.

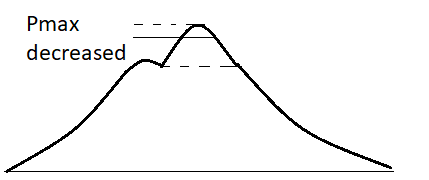

a. Early ignition

Ignition point starts earlier resulting in a higher Pmax, but Pcom is the same. Exhaust temperatures decrease and it may cause knocking. It is corrected by adjusting the FQS setting for bad quality fuel or injection timings.

b. Late ignition after-burning

Observe that the ignition point starts later and Pmax is lower but Pcom is the same. Exhaust temperature decrease as more fuel is burnt later and smoke increases. The cause are wrong fuel pump timings, camshaft drive wear, worn fuel pump plunger, faulty delivery valve or suction valve spring, injector nozzle trumplets, or worn injector holes.

c. Pressure Oscillations.

Observe the oscillations are due to the gas column or indicator drive. To use this diagram, take the mean of the oscillation amplitude to get the curve.

d. High compression pressure

Observe that the Pcom is high, resulting in a higher Pmax. Ignition point is higher although there is late ignition.

e. Low compression pressure

Observe Pcom is lower, resulting in a lower Pmax and early ignition.

f. Leaky exhaust valve or worn piston rings

Observe Pcom is lower and ignition point is later. Pmax and exhaust temperature increases, while power decreases.

g. Overloaded engine

Observe Pcom is higher and Pmax is higher. exhaust temperature and smoke increases.

h. Leaky injector or a worn fuel pump

Observe Pcom is same while there is a fluctuating pressure in the expansion stroke after the ignition point. Pmax and power decrease. Injection is done later and smoke increases.

i. Choked intake

Observe that due to a choke intake compression pressure is less throughout the curve. It results in a lower Pcom and Pmax, while exhaust temperature and smoke increases. The turbocharger surges.

Analysis of compression card

When the lines are not coinciding. If the compression card is positive in area and hence, the indicator cam should be retarded. This implies that the indicator cam setting is wrong.

If the compression card is negative in area and hence the indicator cam should be advanced. This implies that the indicator cam setting is wrong.

Analysis of light Spring Diagram

a. Choked intake

The dashed line indicates the ideal curve, while the dark line indicated the actual curve.

b. Early opening of the exhaust valve

Observe the exhaust valve opening point has shifted to an earlier position. Power decreases and exhaust temperatures increase.

c. Late opening of exhaust valve

Observe the exhaust valve opening point has shifted to a later position. Scavenge efficiency decreases and less energy is passes to the turbocharger.

d. Choked exhaust

Observe that the exhaust is choked, there is less pressure throughout. Exhaust temperatures and smoke increase. Scavenging efficiency decreases and there is a possibility of turbocharger surging.

Faults With Indicator Instruments

a. Vibrations in the indicator instrument drive. Only the power card is affected, while the draw card is not affected.

b. Cord of the indicator instrument is too long. Hence, the TDC section is missing.

c. Cord is too short. Hence, the BDC part is missing.

d. Friction in the indicator piston. Observe that both power and draw cards are affected. It results in an extra large working diagram area.

e. Weak spring of the indicator instrument. It results in the indicator piston striking the top end of the cylinder.

f. Leaking indicator cock. Observe that the atmosphere datum line is untrue.

All indicator cards faulty indicates that the problem is with spring tension, piston freeness, deposits, linkages, drum cord, clear indicator cock, etc.

Mainly on account of the compressibility of the fuel, the commencement of fuel delivery by the fuel pump and the commencement of the fuel injection do not coincide in relation to the time.

The result is a time-lag, A — B. The distance B — C represents the Ignition lag. This is the time which elapses between commencement of fuel injection and the first perceivable increase of pressure. The Ignition lag is the characteristic of the fuel. Large lag indicates unsuitability of the fuel.

When the pressure rises rapidly, the combustion and expansion curves show vibrations, due to a fault in the. spring. The diagram is then evaluated, to obtain the actual maximum pressure.

Ans: It is important to keep the difference between the maximum combustion pressure (peak pressure) and the compression pressure below 40 bar. If this pressure difference is too large, the piston ring may get damaged (ring collapse/breakage).

The combustion gases may pass through the ring pack, resulting in damage to liner, increased heat load on the liner and rings. In extreme cases, this may result in the sticking of the piston rings and hair-line cracks in the liner due to overheating.

The capability of the Piston rings to withstand the pressure shocks depends upon

- Design and material aspects.

- Rate of pressure rise.

- Engine load.

- Cylinder oil feed rate.

- Quality of cylinder lubricant.

- Lower Scavenge air pressure.

- Fouled turbocharger inlet filters.

- Fouled Scavenge air coolers.

- Burnt Piston crown.

- Leaky Piston rings.

- Worn Cylinder liner.

- Burnt Exhaust valves.

- Change in Exhaust valve timing.

a. Friction between rubbing components causes distortion of the card. Friction can be reduced by keeping the indicator piston and cylinder clean and lightly lubricated with a few drops of oil.

b. The close fit of piston should be checked, it should be dismantled, and the piston is allowed to fall freely under its own weight.

When the bottom is covered, the piston should hold its position, this will only happen if there is proper sealing, with minimal clearance.

c. The indicator drum should not hit the end-stops, when the cord is connected.

d. There should be negligible 'play' in the stylus linkages.

e. The indicator cock should be free of carbon and combustion residues, by blowing- through before use.

f. The Indicator should only be kept on the cock as long as necessary, else it will tend to over-heat, and give a distorted card. The instrument should be allowed to cool down in between usage.

g. Use proper gloves while handling the Indicator, which provide protection from the heat, without restricting movement

a. Early injection

b. Late injection

c. Afterburning

d. Loss of compression

e. Chocked intake/Silencer

f. Chocked exhaust

- compression pressure,

- maximum pressure of ignition and the

- nature of the expansion curve.

- Loss of compression,

- defective fuel pump timing,

- unsuitable fuel

- occurrence of afterburning etc.

- Ship speeds have been lowered.

- Reduce engine speed by increasing stroke. .

- Stem apertures of vessels have been redesigned to accommodate larger diameter propellers.

- Hydrodynamic improvements have been introduced by refining stem lines, increasing beam ratios and adding all sorts of propulsion aids. e.g. ducts, fins, vane wheels, bulbs, asymmetric stems, flow straightening nozzles, propeller boss cap fins. etc.

- Compression pressure;

- Crank angle at Pmax point;

- Pmax;

- Expansion pressure;

- Fuel pump index;

- Exhaust gas temperature.

- When the speed is high the indicator piston, its spring and stylus Will be unable to follow the pressure of the main cylinder due to inertia lag. Too rapid fluctuation of pressure is likely to create oscillations interfering with the proper functioning of the stylus. Higher level of engine vibration is likely to be transmitted to the instrument.

- The variation of pressure is large and rapid. A heavy spring does not respond quickly when the cycle pressure is low. When the clearance volume is small the additional volume of the piping leading to the instrument lowers the compression ratio.

- The limitation of the indicator instrument is the rate of change of pressure. With higher rate, a helical spring is unsuitable as its natural frequency of vibration is low.

Comments

Post a Comment