MARPOL-1973/1997

Marpol Annex VI

Regulation 1-11:- Special areas

Regulation 12:- Tanks for oil Residues (sludge)

Regulation 13:- Standard discharge connection

Regulation 15:- Control of discharge of oil

Regulation 17:- (ORB) Oil Record Book, Part 1- Machinery space operations

Regulation 27:- Intact Stability

Regulation 28:- Subdivision and Damage stability

Regulation 31:- Oil discharge monitoring and control system

Regulation 32:- Oil/water interface detector

Regulation 33:- Crude oil washing requirements

Regulation 34:- Control of discharge of oil

Regulation 36:- Oil Record Book, Part-II- Cargo/Ballast operation

MARPOL Annex-I

Regulation 1-11:- Special areas

Regulation 12:- Tanks for oil Residues (sludge)

Regulation 13:- Standard discharge connection

Regulation 15:- Control of discharge of oil

Regulation 17:- (ORB) Oil Record Book, Part 1- Machinery space operations

Regulation 27:- Intact Stability

Regulation 28:- Subdivision and Damage stability

Regulation 31:- Oil discharge monitoring and control system

Regulation 32:- Oil/water interface detector

Regulation 33:- Crude oil washing requirements

Regulation 34:- Control of discharge of oil

Regulation 36:- Oil Record Book, Part-II- Cargo/Ballast operation

Regulation 1-11:- Special areas

1. The Mediterranean sea area

2. The Baltic sea area

3. The Black sea area

4. The Red sea area

5. The Gulf area.

6. The Gulf of Aden area.

7. The Antarctic area.

8. The Northwest European waters.

9. Oman areas of Arabian sea.

10. Southern South African waters.

Regulation 12:- Tanks for oil Residues (sludge)

1. Every ship of 400GT and above shall be provided with a tank or tanks of adequate capacity, having regard to the type of machinery and length of the voyage, to receive the oil residues (sludge) which can not be delt otherwise in accordance to the requirements of this Annex, such as those resulting from purification of fuel and lubricating oils and oil leakages in the machinery spaces.

2. Piping to and from sludge tanks shall have no direct connection overboard, other than the standard discharge connection referred to in regulation 13.

3. In ships delivered after 31 Dec 1979, tanks for oil residues shall be designed and constructed so as to facilitate their cleaning and the discharge of residues to reception facilities. Ships delivered on or before 31 Dec 1979, shall comply with this regulation as far as reasonable and practicable.

Regulation 13:- Standard discharge connection.

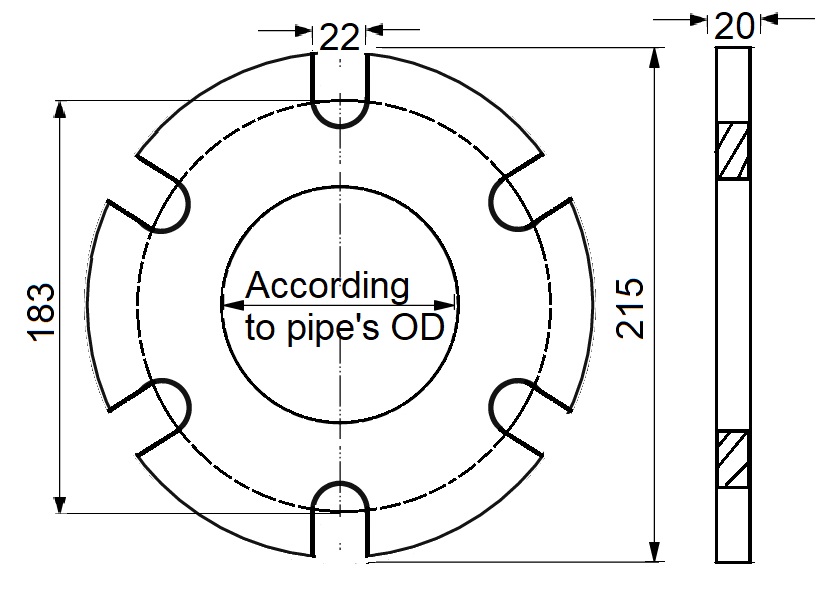

To enable pipes of reception facilities to be connected with the ship's discharge pipeline for residues from machinery bilges and from sludge tanks, both lines shall be fitted with standard discharge connection in accordance with the following table.

Regulation 14:- Oil filtering equipment

1. Except as specified in paragraph 3 of this regulation, any ship of 400GT & above but less than 10,000GT shall be fitted with oil filtering equipment complying with paragraph 6 of this regulation. Any such ship which may discharge into sea ballast in oil fuel tanks in accordance with regulation 16.2 shall comply with paragraph 2 of this regulation.

2. Except as specified in paragraph 3 of this regulation, any ship of 10,000GT & above shall be fitted with oil filtering equipment complying with paragraph 7 of this regulation.

3. Ships, such as hotel ships, storage vessels, etc., which are stationary except for non-cargo-carrying relocation voyages need not be provided with oil filtering equipment. Such ships shall be provided with a holding tank having a volume adequate to the satisfaction of the administration, for the total retention on board of the oily bilge water. All oily bilge water shall be retained on board for subsequent discharge to reception facilities.

4. The Administration shall ensure that ships of less than 400GT are equipped, as far as practicable, to retain on board oil or oily mixtures or discharge them in accordance with the requirements of regulation 15.6 of this annex.

5. The Administration may waive the requirements of paragraph 1 and 2 of this regulation for:

(1) any ship engaged exclusively on voyages within special areas, or

(2) any ship certified under the International Code of safety for high-speed craft (or otherwise within the scope of this Code with regard to size and design) engaged on a scheduled service with a turn-around time not exceeding 24hours and covering also non-passenger/cargo relocation voyages for these ships.

(3) with regard to the provision of subparagraph 1 & 2 above, the following condition shall be complied with: (i) the ship is fitted with a holding tank having a volume adequate, to the satisfaction of administration, for the total retention on board for the oily bilge water;

(ii) all oily bilge water is retained on board for subsequent discharge to reception facilities;

(iii) the Administration has determined that adequate reception facilities are available to receive such oily bilge water in sufficient number of ports or terminals the ship calls at;

(iv) the international oil pollution prevention certificate when required, is endorsed to the effect that the ship is exclusively engaged on the voyages within special areas or has been accepted as high speed craft for the purpose of this regulation and the service is identified; and

(v) the quantity, time, and port of the discharge are recorded in oil record book part I.

6. Oil filtering equipment referred to in paragraph 1 of this regulation shall be of a design approved by the Administration and shall be such as will ensure that any oily mixture discharged into the sea after passing through the system has an oil content not exceeding 15 parts per million. In considering the design of such equiprnent, the Administration shall have regard to the specification recommended by the Organization.

7. Oil filtering equipment referred to in paragraph 2 of this regulation shall comply with paragraph 6 of this regulation. In addition, it shall be provided with alarm arrangement to indicate when this level cannot be maintained. The system shall also be provided with arrangements to ensure that any discharge of oily mixtures is automatically stopped when the oil content of the effluent exceeds 15 parts per million. In considering the design of such equipment and approvals, the Administration shall have regard to the specification recommended by the Organization.

Regulation 15:- Control of discharge of oil

1. Subject to the provisions of regulation 4 of this annex and paragraphs 2, 3. and 6 of this regulation, any discharge into the sea of oil or oily mixtures from ships shall be prohibited.

A. Discharges outside special areas

2. Any discharge into the sea of oil or oily mixtures from ship of 400 gross tonnage and above shall be prohibited except when all the following conditions are satisfied:

(1) the ship is proceeding en route;

(2) the oily mixture is processed through an oil filtering equipment meeting the requirements of regulation 14 of this Annex;

(3) the oil content of the effluent without dilution does not exceed 15 parts per million;

(4) the oily mixture does not originate from cargo pump-room bilges on oil tankers; and

(5) the oily mixture, in case of oil tankers, is not mixed with oil cargo residues.

B. Discharges in special areas

3. Any discharge into the sea of oil or oily mixtures from ships of 400 gross tonnage and above shall be prohibited except when all of the following conditions are satisfied:

(1) the ship in proceeding en route;

(2) the oily mixture is processed through an oil filtering equipment meeting the requirements of regulation 14.7 of this Annex;

(3) the oil content of the effluent without dilution does not exceed 15 parts per million;

(4) the oily mixture does not originate from cargo pump-room bilges on oil tankers; and

(5) the oily mixture, in case of oil tankers, is not mixed with oil cargo residues.

4. In respect of the Antarctic area, any discharge into the sea of oil or oily mixtures from any ship shall be prohibited.

5. Nothing in this regulation shall prohibit a ship on a voyage only part of which is in a special area from discharging outside a special area in accordance with paragraph 2 of this regulation.

C. Requirements for ships of less than 400 gross tonnage in all areas except the Antarctic area

6. In the case of a ship of less than 400 gross tonnage, oil and all oily mixtures shall either be retained on board for subsequent discharge to reception facilities or discharged into the sea in accordance. with the following provisions:

(1) the ship is proceeding en route;

(2) the ship has in operation equipment of a design approved by the Administration that ensures that the oil content of the effluent without dilution does not exceed 15 parts per million;

(3) the oily mixture does not originate from cargo pump-room bilges on oil tankers; and

(4) the oily mixture, in case of oil tanker is not mixed with oil cargo residues.

D. General requirements

7. Whenever visible traces of oil are observed on or below the surface of the water in the immediate vicinty of a ship or its wake, Governments of Parties to the present'Convention should, so the extent they are reasonably able to do so, promptly investigate the facts bearing on the issue of whether there has been a violation of the provisions of this regulation. The investigation should include, in particular, the wind and sea condition, the track and speed of the ship, other possible sources of the visible traces in the vicinity, and any relevant oil discharge records.

8. No discharge into the sea shall contain chemicals or other substances in quantities or concentrations which are hazardous to the marine environment or chemicals or other substances introduced for the purpose of circumventing the conditions of discharge specifed in this regulation.

9. The oil residues which cannot be discharged into the sea in compliance with this regulation shall be retained on board for subsequent discharge to reception facilities.

Regulation 17 (ORB) Oil Record Book, Part 1- Machinery space operations

1. Every oil tanker of 150 gross tounage and above and every ship of 400 Gross tonnage and above other than an oil tanker shall be provided with an Oil Record Book Part I (Machinery space operations). The Oil Record Book, whether as a part of the ship's official log-book or otherwise, shall be in the form specibed in appendix III to this Annex.

2. The Oil Record Book Part I shall be completed on each occasion, on a tank-to-tank basis if appropriate, whenever any of the following muchinery space operations takes place in the ship:

(1) ballasting or cleaning of oil fuel tanks,

(2) discharge of dirty ballast or cleaning water from oil fuel tanks;

(3) collection and disposal of oil residues (sludge)

(4) discharge overboard or disposal otherwise of bilge water which has accumulated in machinery spaces; and

(5) bunkering of fuel or bulk lubricating oil.

3. In the event of such discharge of oil or oily mixnure as is referred to in regulation 4 of this Annex or in the event of accidenal or other exceptional dicharge of oil not excepted by that regulation, a statement shall be made in the Oil Record Book Part I of the circumstances of, and the reason for, the discharge.

4. Each operation described in paragaph 2 of this regulation shall be fully recorded without delay in the Oil Record Book Part 1, so that all entries in the book appropriate to that operation are completed. Each completed operation shall be signed by the officer or officers in charge of the operations concerned and cach completed page shall be signed by the master of ship. The entries in the Oil Record Book Part I, for ships holding an International oil pollution prevention certificate, shall be atleast in english, french or spanish. Where entries in an official national language of the state whose flag the ship is entitled to fly are also used, this shall prevail in case of a dipute or discrepancy.

5. Any failure of the oil filtering equipment shall be recorded in the Oil Record Book Part I.

6. The Oil Record Book Part I shall be kept in such a place as to be readily availabie for inspection at all reasonable times and, except in the case of unmanned ships under tow, shall be kept on board the ship. It shall be preserved for a period of three years after the last entry has been made. The competent authority of the Government of a Party to the present Convention may inspect the Oil Record Book Part I on board any ship to which this Annex applies while the ship is in its port or offshore terminals and may make a copy of any entry in that book and may require the master of the ship to certify that the copy is a true copy of such entry. Any copy so made which has been certified by the master of the ship as a true copy of an entry in the ship's Oil Record Book Part I shall be made admissible in any judicial proceedings as evidence of the facts stated in the entry. The inspection of an Oil Record Book Part I and the taking of a ceritified copy by competent authority under this paragraph shall be performed as expeditiously as possible without causing the ship to be unduly delayed.

Regulation 27:- Intact Stability

1 Every oil tanker of 5,000 tonnes deadweight and above delivered on or after 1 February 2002, as defined in regulation 1.28.7, shall comply with the intact stability criteria specified in paragraphs 1.1 and 1.2 of this regulation, as appropriate, for any operating draught under the worst possible conditions of cargo and ballast loading, consistent with good operational practice, including intermediate stages of liquid transfer operations. Under all conditions the ballast tanks shall be assumed slack.

.1 In port, the initial metacentric height GMo, corrected for the free surface measured at 0° heel, shall be not less than 0.15 m;

.2 At sea, the following criteria shall be applicable:

.2.1 the area under the righting lever curve (GZ curve) shall be not less than 0.055 m·rad up to θ = 30° angle of heel and not less than 0.09 m·rad up to θ = 40° or other angle of flooding θf* if this angle is less than 40°. Additionally, the area under the righting lever curve (GZ curve) between the angles of heel of 308 and 40° or between 30° and θf, if this angle is less than 40°, shall be not less than 0.03 m·rad;

.2.2 the righting lever GZ shall be at least 0.20 m at an angle of heel equal to or greater than 30°;

.2.3 the maximum righting arm shall occur at an angle of heel preferably exceeding 30° but not less than 25°; and

.2.4 the initial metacentric height GMo, corrected for free surface measured at 0° heel, shall be not less than 0.15 m.

2 The requirements of paragraph 1 of this regulation shall be met through design measures. For combination carriers simple supplementary operational procedures may be allowed.

3 Simple supplementary operational procedures for liquid transfer operations referred to in paragraph 2 of this regulation shall mean written procedures made available to the master which:

.1 are approved by the Administration;

.2 indicate those cargo and ballast tanks which may, under any specific condition of liquid transfer and possible range of cargo densities, be slack and still allow the stability criteria to be met. The slack tanks may vary during the liquid transfer operations and be of any combination provided they satisfy the criteria;

.3 will be readily understandable to the officer-in-charge of liquid transfer operations;

.4 provide for planned sequences of cargo/ballast transfer operations;

.5 allow comparisons of attained and required stability using stability performance criteria in graphical or tabular form;

.6 require no extensive mathematical calculations by the officer-incharge;

.7 provide for corrective actions to be taken by the officer-incharge in case of departure from recommended values and in case of emergency situations; and

.8 are prominently displayed in the approved trim and stability booklet and at the cargo/ballast transfer control station and in any computer software by which stability calculations are performed.

* θf is the angle of heel at which openings in the hull superstructures or deckhouses which cannot be closed weathertight immerse. In applying this criterion, small openings through which progressive flooding cannot take place need not be considered as open.

Regulation 28:- Subdivision and Damage stability

3 Oil tankers shall be regarded as complying with the damage stability criteria if the following requirements are met:

.1 The final waterline, taking into account sinkage, heel and trim, shall be below the lower edge of any opening through which progressive flooding may take place. Such openings shall include air-pipes and those which are closed by means of weathertight doors or hatch covers and may exclude those openings closed by means of watertight manhole covers and flush scuttles, small watertight cargo tank hatch covers which maintain the high integrity of the deck, remotely operated watertight sliding doors, and sidescuttles of the non-opening type.

.2 In the final stage of flooding, the angle of heel due to unsymmetrical flooding shall not exceed 25°, provided that this angle may be increased up to 30° if no deck edge immersion occurs.

.3 The stability in the final stage of flooding shall be investigated and may be regarded as sufficient if the righting lever curve has at least a range of 20° beyond the position of equilibrium in association with a maximum residual righting lever of at least 0.1 m within the 20° range; the area under the curve within this range shall not be less than 0.0175 m-rad. Unprotected openings shall not be immersed within this range unless the space concerned is assumed to be flooded. Within this range, the immersion of any of the openings listed in subparagraph 3.1 of this paragraph and other openings capable of being closed watertight may be permitted.

.4 The Administration shall be satisfied that the stability is sufficient during intermediate stages of flooding.

.5 Equalization arrangements requiring mechanical aids such as valves or cross-levelling pipes, if fitted, shall not be considered for the purpose of reducing an angle of heel or attaining the minimum range of residual stability to meet the requirements of subparagraphs 3.1, 3.2 and 3.3 of this paragraph and sufficient residual stability shall be maintained during all stages where equalization is used. Spaces which are linked by ducts of a large cross-sectional area may be considered to be common.

Regulation 31:- Oil discharge monitoring and control system

1. Subject to the provisions of paragraphs 4 and 5 of regulation 3 of this Annex, oil tankers of 150 gross tonnage and above shall be equipped with an oil discharge monitoring and contro! system approved by the Administration.

2. In considering the design of the oil content meter to be incorporated in the system, the Administration shall have regard to the specification recommended by the Organization. The system shall be fitted with a recording device to provide a continuous record of the discharge in litres per nautical mile and total quantity discharged, or the oil content and rate of discharge. This record shall be identifiable as to time and date and shall be kept for at least three years. The oil discharge monitoring and control system shall come into operation when there is any discharge of effluent into the sea and shall be such as will ensure that any discharge of oily mixture is automitically stopped when the instantancous rate of discharge of oil exceeds that permitted by regulation 34 of this Annex. Any filure of this monitoring and control system shall stop the discharge. In the event of failure of the oil discharge moritoring and control system a manually operated alternative method may be used, but the defective unit shall be made operable as soon as possible. Subject to allowance by the port State authority, a tanker with a defective oil discharge monitoring and control system may undertake one ballast voyage before proceeding to a repair port.

3. The oil discharge monitoring and control system shall be designed and installed in compliance with the guidelines and specifications for oil discharge monitoring and control systems for oil tankers developed by the Organization. Administrations may accept such specific arrangèments as detailed in the Guidelines and Specifications.

4. Instructions as to the operation of the system shall be in accordance with an operational manual approved by the Administration. They shall cover manual as well as automatic operations and shall be intended to ensure that at no time shall oil be discharged except in compliance with the conditions specified in regulation 34 of this Annex.

Regulation 32:- Oil/water interface detector

Subject to the provisions of paragraphs 4 and 5 of regulation 3 of this Annex, oil tankers of 150 gross tonnage and above shall be provided with effective oil/water interface detectors approved by the Administration for a rapid and accurate determination of the oil/water interface in slop tanks and shall be available for use in other tanks where the separation of oil and water is effected and from which it is intended to discharge effluent direct to the sea.

Regulation 33:- Crude oil washing requirements

1. Every crude oil tanker of 20,000 tonnes deadweight and above delivered after 1 June 1982, shall be fitted with a cargo tank cleaning system using crude oil washing. The Administration shall ensure that the system fully complies with the requirements of this regulation within one year after the tanker was first engaged in the trade of carrying crude oil or by the end of the third voyage carrying crude oil suitable for crude oil washing, whichever occurs later.

2. Crude oil washing installation and associated equipment and arrangements shall comply with the requirements established by the Administration. Such requirements shall contain at least all the provisions of the Specifications for the Design, Operation and Control of Crude Oil Washing Systems adopted by the Organization When a ship is not required, in accordance with paragraph 1 of this regulation to be, but is equipped with crude oil washing equipment, it shall comply with the safety aspects of the above mentioned Specifications.

3. Every crude oil washing systerm required to be provided in accordance with regulation 18.7 of this Annex shall comply with the requirements of this regulation.

Regulation 34:- Control of discharge of oil

A. Discharges outside special areas

1. Subject to the provisions of regulation 4 of this Annex and paragraph 2 of this regulation, any discharge into the sea of oil or oily mixtures from the cargo area of an oil tanker thall be prohibited except when all the following conditions are satisfied:

(i) the tanker is not within a special area;

(ii) the tanker is more than 50 nautical miles from the nearest land,

(iii) the tanker is proceeding en route;

(iv) the instantancous rate of discharge of oil content does not exceed 30 litres per nautical mile;

(v) the total quantity of oil discharged into the sea does not exceed for tankers delivered on or before 31 December 1979, 1/15,000 of the total quantity of the particular cargo of which the residuce formed a part, and for tankers delivered after 31 December 1979, 1/30,000 of the total quantity of the particular cargo of which the residue formed a part; and

(vi) the tanker has in operation an oil discharge monitoring and control system and a slop tank arrangement as required by regulations 29 and 31 of this Annex.

2. The provisions of paragraph 1 of this regulation shall not apply to the discharge of clean or segregated ballast.

B. Discharges in special areas.

3. Subject to the provisions' of paragraph 4 of this regulation, any discharge into the sea of ol or odly. mixture from the cargo arca of an oil tanker shall be prohibited while in a special area.

4. The provisions of paragraph 3 of this regulation shall not apply to the discharge of clean or segregated ballast.

5. Nothing in this regulation shall prohibit a ship on a voyage only part of which is in a special area from discharging outside the special area in accordance with paragraph 1 of this regulation.

C Requirements for oil tankers of less than 150 gross tonnage

6. The requirements of regulations 29, 31 and 32 of this Annex shall not apply to oil tankers of less than 150 gross tonnage, for which the control of discharge of oil under this regulation shall be cliccied by the retention of oil on board with subsequent discharge of alll conuminated washings to recepion facilides. The total quantity of oil and water used for washing and returned to a stonge tank shall be discharged to reception facilities unless adequate arrangements are made to ensure that any effluent which is allowed to be discharged into the sea is effecively monitored to ensure that the provisions of this regulation are complied with.

D.General requirements

7. Whenever visible traces of oil are observed on or below the surface of the water in the immediate vicinity of a ship or its wake, the Governments of Parties to the present Convention should, to the extent they are reasonably able to do so, promptly investigate the facts bearing on the issue of whether there has been a violation of the provisions of this regulation. The investigation should include, in particular, the wind and sea conditions, the track and speed of the ship, other possible sources of the visible traces in the vicinity, and any relevant oil discharge records.

8. No discharge into the sea shall contain chemicals or other substances in quantities or concentrations which are hazardous to the marine environment or chemicals or other substances introduced for the purpose of circumventing the conditions of discharge specified in this regulation.

9. The oil residue which can not be discharge into the sea in compliance with paragraphs 1 and 3 of this regulation shall be retained on board for subsequent discharge to reception facilities.

Regulation 36:- Oil Record Book, Part-II- Cargo/Ballast operation

1. Every oil tanker ot 150 gross tonnage and above shall be provided with an Oil Record book Part II (Cargo/Ballast Operations). The Oil Record Book Part II, whether as a part of the ship's official log-book or otherwise, shall be in the form specified in appendix III to this Annex.

2. The Oil Record Book Part II shall be completed on cach occasion, on a tank-to-tank basis if appropriate, whenever any of the following cargo/ ballast operations take place in the ship

(1) loading of oil cargo;

(2) internal transfer of oil cargo during voyage;

(3) unloading of oil cargo;

(4) ballasting of cargo tanks and dedicated clean ballast tanks;

(5) cleanıng of cargo tanks including crude oil washing;

(6) discharge of ballast except from segregated ballast tanks;

(7) discharge of water from slop tanks;

(8) closing of all applicable valves or similar devices after slop tank discharge operations;

(9) closing of valves necessary for isolation of dedicated clean ballast tanks from cargo and stripping lines after slop tank discharge operation;

(10) disporal of residues.

3. For oil tankers referred to in regulation 34.6 of this Annex, the total quantity of oil and water used for washing and returned to a storage tank shall be recorded in the Oil Record Book Part II.

4. In the event of such discharge of oil or oily mixture as is referred to in regulation 4 of this Annex or in the event of accidental or other exceptional discharge of oil not excepted by that regulation, a statement shall be made in the Oil Record Book Part II of the circumstances of, and the reasons for, the discharge.

5. Each operation described in paragaph 2 of this regulatioh shall be fully recorded without delay in the Oil Record Book Part II so that all entries in the book appropriate to that operaton are completed. Each completed operation shall be signed by the officer or officers in charge of the operations concerned and each completed page shall be signed by the master of ship. The entries in the Oil Record Book Part II shall be at least in English, French or Spanish. Where entries in an official language of the State whose flag the ship is entitled to fly are also used, this thall prevail in case of dispute or diserepancy.

6. Any filure of the oil discharge monitoring and control system shall be noted in the Oil Record Book Part II.

7. The Oil Recard Book thall be kept in such a place as to be readily available for inspection at all reasonable times and, except in the case of unmanned ships under tow, shall be kept on beard the ship. It shall be preserved for a period of three years after the last entry has been made.

8. The competent authority of the Government of a Party to the Convention may inspect the Oil Record Book Part II on board any ship to which this Annex applies while the ship is in its port or offshore terminals and may make a copy of any entry in that book and may require the master of the ship to verify that the copy is a true copy of such entry. Any copy so made which has been certifed by the master of the ship as a true copy of an entry in the ship's Oil Record Book Part II shall be made admissible in any proceedings as evidence of the facts stated in the entry. The inspection of an Oil Record Book Part II and the taking of a certified copy by the competent authority under this paragraph shall be performed as expeditiously as possible without causing the ship to be unduly delayed.

9. For oil tankers of less than 150 gross tonnage operating in accordance with regulation 34.6 of this Annex, an appropriate Oil Record Book should be developed by the Administration.

MARPOL Annex-II

Regulation 6:- Categorization and listing of Noxious Liquid Substances and other substances

Regulation 13:- Control of discharges of residues of Noxious Liquid Substances

Regulation 14:- Procedures and Arrangements Manual

Regulation 15:- Cargo record book

Special areas:- "Antarctic Area" & as per polar code More stringent discharge criteria at "Arctic waters"

Regulation 6:- Categorization and listing of Noxious Liquid Substances and other substances

For the purpose of the regulations of this Annex, Noxious Liquid Substances shall be divided into four categories as follows:

Category X: Noxious Liquid Substances which, if discharged into the sea from tank cleaning or de-ballasting operations, are deemed to present a major hazard to either marine resources or human health and, therefore, justify the prohibition of the discharge into the marine environment;

Category Y: Noxious Liquid Substances which, if discharged into the sea from tank cleaning or de-ballasting operations, are deemed to present a hazard to either marine resources or human health or cause harm to amenities or other legitimate uses of the sea and therefore justify a limitation on the quality and quantity of the discharge into the marine environment;

Category Z: Noxious Liquid Substances which, if discharged into the sea from tank cleaning or de-ballasting operations, are deemed to present a minor hazard to either marine resources or human health and therefore justify less stringent restrictions on the quality and quantity of the discharge into the marine environment;

Other Substances: substances indicated as OS (Other Substances) in the pollution category column of chapter 18 of the International Bulk Chemical Code which have been evaluated and found to fall outside Category X, Y or Z as defined in regulation 6.1 of this Annex because they are, at present, considered to present no harm to marine resources, human health, amenities or other legitimate uses of the sea when discharged into the sea from tank cleaning of de-ballasting operations. The discharge of bilge or ballast water or other residues or mixtures containing only substances referred to as "Other Substances" shall not be subject to any requirements of the Annex.

Regulation 13:- Control of discharges of residues of Noxious Liquid Substances

Subject to the provisions of regulation 3 of this Annex the control of discharges of residues of Noxious Liquid Substances or ballast water, tank washings or other mixtures containing such substances shall be in compliance with the following requirements.

1.Discharge provisions

1.1 The discharge into the sea of residues of substances assigned to Category X, Y or Z or of those provisionally assessed as such or ballast water, tank washings or other mixtures containing such substances shall be prohibited unless such discharges are made in full compliance with the applicable operational requirements contained in this Annex.

1.2 Before any prewash or discharge procedure is carried out in accordance with this regulation, the relevant tank shall be emptied to the maximum extent in accordance with the procedures prescribed in the Manual.

1.3 The carriage of substances which have not been categorized, provisionally assessed or evaluated as referred to in regulation 6 of this Annex or of ballast water, tank washings or other mixtures containing such residues shall be prohibited along with any consequential discharge of such substances into the sea.

2. Discharge standards

1. Where the provisions in this regulation allow the discharge into the sea of residues of substances in Category X, Y or Z or of those provisionally assessed as such or ballast water, tank washings or other mixtures containing such substances the following discharge standards shall apply:

(i) the ship is proceeding enroute at a speed of at least 7 knots in the case of self-propelled ships or at least 4 knots in the case of ships which are not self-propelled

(ii) the discharge is made below the waterline through the underwater discharge outlet(s) not exceeding the maximum rate for which the underwater discharge outlet(s) is (are) designed; and the discharge is made at a distance of not less than 12 nautical miles from the nearest land in a depth of water of not less than 25 metres.

2. For ships constructed before 1 January 2007 the discharge into the sea of residues of substances in Category Z or of those provisionally assessed as such or ballast water, tank washings or other mixtures containing such substances below the waterline is not mandatory.

3. The Administration may waive the requirements of paragraph 2.1.3 for substances in Category Z, regarding the distance of not less than 12 nautical miles from the nearest land for ships solely engaged in voyages within waters subject to the sovereignty or jurisdiction of the State the flag, of which, the ship is entītled to fly. In addition, the Administration may waive the same requirement regarding the discharge distance of not less than 12 nautical miles from the nearest land for a particular ship entitled to fly the flag of their State, when engaged in voyages within waters subject to the sovereignty or jurisdiction of one adjacent state after the establishment of an agreement, in writing, of a waiver between the two coastal States involved provided that no third party will be affected. Information on such agreement shall be communicated to the Organization within 30 days for further circulation to the Parties to the Convention for their information and appropriate action if any.

3. Ventilation of cargo residues

Ventilation procedures approved by the Administration may be used to remove cargo residues from a tank. Such procedures shall be in accordance with appendix 7 of this Annex. Any water subsequently introduced into the tank shall be regarded as clean and shall not be subject to the discharge requirements in this Annex.

4. Exemption for a prewash

On request of the ship's master an exemption for a prewash may be granted by the Government of the receiving Party, where it is satisfied that:

(i) the unloaded tank is to be reloaded with the same substance or another substance compatible with the previous one and that the tank will not be washed or ballasted prior to loading; or

(ii) the unloaded tank is neither washed nor ballasted at sea. The prewash in accordance with the applicable paragraph of this regulation shall be carried out at another port provided that it has been confirmed in writing that a reception facility at that port is available and is adequate for such a purpose; or

(iii)the cargo residues will be removed by a ventilation procedure approved by the Administration in accordance with appendix 7 of this Annex.

5. The use of cleaning agents or additives

(i) When a washing medium other than water, such as mineral oil or chlorinated solvent, is used instead of water to wash a tank, its discharge shall be governed by the provisions of either Annex I or Annex II, which would apply to the medium had it been carried as cargo. Tank washing procedures involving the use of such a medium shall be set out in the Manual and be approved by the Administration. (ii) When small amounts of cleaning additives (detergent products) are added to water in order to facilitate tank washing, no additives containing Pollution Category X components shall be used except those components that are readily biodegradable and present in a total concentration of less than 10% of the cleaning additive. No restrictions additional to those applicable to the tank due to the previous cargo shall apply.

6. Discharge of residues of Category X

Subject to the provision of paragraph 1, the following provisions shall apply:

(1) A tank from which a substance in Category x has been unloaded, shall be prewashed before the ship leaves the port of unloading. The resulting residues shall be discharged to a reception facility until the concentration of the substance in the effluent to such facility, as indicated by analyses of samples of the effluent taken by the surveyor, is at or below 0.1% by weight. When the required concentration level has been achieved, remaining tank washings shall continue to be discharged to the reception facility until the tank is empty. Appropriate entries of these operations shall be made in the Cargo Record Book and endorsed by the surveyor referred to in regulation 16.1.

(2) Any water subsequently introduced into the tank may be discharged into the sea in accordance with the discharge standards in regulation 13.2.

(3) Where the Government of the receiving party is satisfied that it is impracticable to measure the concentration of the substance in the effluent without causing undue delay to the ship, that Party may accept an alternative procedure as being equivalent to obtain the required concentration in regulation 13.6.1.1 provided that:

(i) the tank is prewashed in accordance with a procedure approved by the Administration in compliance with appendix 6 of this Annex; and

(ii) appropriate entries shall be made in the Cargo Record Book and endorsed by the surveyor referred to in regulation 16.1.

7 Discharge of residues of Category Y and Z

(i) Subject to the provision of paragraph 1, the following provisions shall apply:

(a) With respect to the residue discharge procedures for substances in Category Y or Z the discharge standards in regulation 13.2 shall apply.

(b) If the unloading of a substance of Category Y or Z is not carried out in accordance with the Manual, a prewash shall be carried out before the ship leaves the port of unloading, unless alternative measures are taken to the satisfaction of the surveyor referred to in regulation 16. 1 of this Annex to remove the cargo residues from the ship to quantities specified in this Annex. The resulting tank washings of the prewash shall be discharged to a reception facility at the port of unloading or another port with a suitable reception facility provided that it has been confirmed in writing that a reception facility at that port is available and is adequate for such a purpose.

(c) For High-Viscosity or Solidifying Substances in Category Y the following shall apply:

➤a prewash procedure as specified in appendix 6 shall be applied;

➤the residue/water mixture generated during the prewash shall be discharged to a reception facility until the tank is empty; and

➤any water subsequently introduced into the tank may be discharged into the sea in accordance with the discharge standards in regulation 13.2.

(ii) Operational requirements for ballasting and de-ballasting

(a) After unloading, and, if required, after a prewash, a cargo tank may be ballasted. Procedures for the discharge of such ballast are set out in regulation 13.2.

(b) Ballast introduced into a cargo tank which has been washed to such an extent that the ballast contains less than 1 ppm of the substance previously carried, may be discharged into the sea without regard to the discharge rate, ship's speed and discharge outlet location, provided that the ship is not less than 12 miles from the nearest land and in water that is not less than 25 metres deep. The required degree of cleanliness has been achieved when a prewash as specified in appendix 6 has been carried out and the tank has been subsequently washed with a complete cycle of the cleaning machine for ships built before 1 July 1994 or with a water quantity not less than that calculated with k=1.0.

(c) The discharge into the sea of clean or segregated ballast shall not be subject to the requirements of this Annex.

8. Discharges in the Antarctic Area

(i)Antarctic Area means the sea area south of latitude 60°S.

(ii) In the Antarctic area any discharge into the sea of Noxious Liquid Substances or mixtures containing such substances is prohibited.

Regulation 14:- Procedures and Arrangements Manual

1. Every ship certified to carry substances of Category X, Y or Z shall have on board a Manual approved by the Administration. The Manual shall have a standard format In compliance with appendix 4 to this Annex. In the case of a ship engaged In International voyages on which the language used is not English, French or Spanish, the text shall Include a translation Into one of these languages.

2. The main purpose of the Manual is to Identify for the ship's officers the physical arrangements and all the operational procedures with respect to cargo handling, tank deaning, slops handling and cargo tank ballasting and deballasting which must be followed in order to comply with the requirements of this Annex.

Regulation 15:- Cargo record book

1. Every ship to which this Annex applies shall be provided with a Cargo Record Book, whether as part of the ship's official logbook or otherwise, In the form specified In appendix 2 to this Annex.

2. After completion of any operation specified In appendix 2 to this Annex, the operation shall be promptly recorded in the Cargo Record Book.

3. In the event of an accidental discharge of a noxious liquid substance or a mixture containing such a substance or a discharge under the provisions of regulation 3 of this Annex, an entry shall be made In the Cargo Record Book stating the circumstances of, and the reason for, the discharge.

4. Each entry shall be signed by the officer or officers In charge of the operation concerned and each page shall be signed by the master of the ship. The entries in the Cargo Record Book, for ships holding an International Pollution Prevention Certificate for the Carriage of Noxious Liquid Substances in Bulk or a certificate referred to in regulation 7 of this Annex shall be at least in English, French or Spanish. Where entries In an official national language of the State whose flag the shipk entitled to fly are also used, this shall prevail in case of a dispute or discrepancy.

5.The Cargo Record Book shall be kept in such a place as to be readily available for inspection and, except in the case of unmanned ships under tow, shall be kept on board the ship. It shall be retained for a period of three years after the last entry has been made.

6.The competent authority of the Government of a Party may inspect the Cargo Record Book on board any ship to which this Annex apples while the ships in Its port, and may make a copy of any entry in that book and may require the master of the ship to certify that the copy is a true copy of such entry. Any copy so made which has been certifed by the master of the ship as a true copy of an entry in the ship's Cargo Record Book shall be made admissible in any judicial proceedings as evidence of the facts stated in the entry. The Inspection of a Cargo Record Book and the taking of a certified copy by the competent authority under this paragraph shall be performed as expeditiously as possible without causing the ship to be unduly delayed.

MARPOL Annex-III

MARPOL Annex-IV

Regulation 9:- Sewage Systems

Regulation 1O:- Standard Discharge Connections

Regulation 11:- Discharge of Sewage

Regulation 9:- Sewage Systems

1. Every ship which, in accordance with regulation 2, is required to comply with the provisions of this Annex shall be equipped with one of the following sewage systems:

(1) a sewage treatment plant which shall be of a type approved by the Administration, taking into account the standards and test methods developed by the Organization', or

(2) a sewage comminuting and disinfecting system approved by the Administration. Such system shall be fitted with facilities to the satisfaction of the Administration, for the temporary storage of sewage when the ship is less than 3 nautical miles from the nearest land, or

(3) a holding tank of the capacity to the satisfaction of the Administration for the retention of all sewage, having regard to the operation of the ship, the number of persons on board and other relevant factors. The holding tank shall be constructed to the satisfaction of the Administration and shall have a means to indicate visually the amount of its contents.

2. By derogation from paragraph 1, every passenger ship which, in accordance with regulation 2, is required to comply with the provisions of this Annex, and for which regulation 11.3 applies while in a special area, shall be equipped with one of the following sewage systems:

(1) a sewage treatment plant which shall be of a type approved by the Admınistration, takıng into account the standards and test methods developed by the Organization, or

(2) a holding tank of the capacity to the satisfaction of the Administration for the retention of all sewage, having regard to the operation of the ship, the number of persons on board and other relevant factors. The holding tank shall be constructed to the satisfaction of the Administration and shall have a means to indicate visually the amount of its contents.

Regulation 1O:- Standard Discharge Connections

1. To enable pipes of reception facilities to be connected with the ship's discharge pipeline, both lines shall be fitted with a standard discharge connection in accordance with the following table:

For ships having a moulded depth of 5 metres and less, the inner diameter of the discharge connection may be 38 millimetres.

2. For ships in dedicated trades, i.e. passenger ferries, alternatively the ship's discharge pipeline may be fitted with a discharge connection which can be accepted by the Administration, such as quick connection couplings.

Regulation 11:- Discharge of Sewage

A. Discharge of sewage from ships other than passenger ships in all areas and discharge of sewage from passenger ships outside special areas

1. Subject to the provisions of regulation 3 of this Annex, the discharge of sewage into the sea is prohibited, except when:

(1) the ship is discharging comminuted and disinfected sewage using a system approved by the Administration in accordance with regulation 9.1.2 of this Annex at a distance of more than 3 nautical miles from the nearest land, or sewage which is not comminuted or disinfected at a distance of more than 12 nautical miles from the nearest land, provided that, in any case, the sewage that has been stored in holding tanks, or sewage originating from spaces containing living animals, shall not be discharged instantaneously but, at a moderate rate when the ship is en route and proceeding at not less than 4 knots; the rate of discharge shall be approved by Administration based upon standards developed by the Organization'; or

(2) the ship has in operation an approved sewage treatment plant which has been certified by the Administration to meet the operational requirements referred to in regulation 9.1.1 of this Annex, and the effluent shall not produce visible floating solids nor cause discoloration of the surrounding water.

2. The provisions of paragraph 1 shall not apply to ships operating in the waters under the jurisdiction of a State and visiting ships from other States while they are in these waters and are discharging sewage in accordance with such less stringent requirements as may be imposed by such State.

B. Discharge of sewage from passenger ships within a special area

3. Subject to the provisions of regulation 3 of this Annex, the discharge of sewage from a passenger ship within a special area shall be prohibited:

(1) for new passenger ships, on a date determined by the Organization pursuant to regulation 13.2 of this Annex, but in no event prior to 1 June 2019; and

(2) for existing passenger ships, on a date determined by the Organization pursuant to regulation 13.2 of this Annex, but in no event prior to 1 June 2021,

except when the following conditions are satisfied:

the ship has in operation an approved sewage treatment plant which has been certified by the Administration to meet the operational requirements referred to in regulation 9.2.1 of this Annex, and the effluent shall not produce visible floating solids nor cause discoloration of the surrounding water.

C. General requirements

4. When the sewage is mixed with wastes or waste water covered by other Annexes of MARPOL, the requirements of those Annexes shall be complied requirements of this Annex.

MARPOL Annex-V

MARPOL Annex-VI

Marpol Annex VI:- Regulation for the Prevention of Air Pollution From Ships

Adaptation

Certification

Ozone depleting substances

NOx control

SOx Control

Volatile Organic Matter

The Incineration of shipboard wastes

Fuel Oil Quality.

NOx technical File

NOx Technical Code

NOx reduction methods

Adaptation

After many year of debate and development, the IMO adopted Annex VI to the Marpol convention in September 1997. The requirements for the Marpol 73/78 Annex VI to come into force were fulfilled on 18th May 2004. Hance the Annex has entered into force on 19th May 2005. This new Annex is entitled "Regulation for the Prevention of Air Pollution From Ships". IMO has also adopted the "Technical Code on control of emissions of Nitrogen Oxides from Marine Diesel Engines", normally referred as the NOx technical code.

Certification:-

Marpol Annex VI applies to all ships, and to fixed and floating drilling rigs and other platforms. Ships of 400 GT & above engaged in International voyages, constructed on or after 19th May 2005, are required to be surveyed and issued with an IAPP (International Air Pollution Prevention) Certificate on delivery of the ship.

For ship of above the category engaged in International voyages, constructed prior to this date, the IAPP certificate must be issued at the first scheduled dry docking after 19th May 2005, but no later than the date of the initial survey while its certificate validity will be maintained by annual, intermediate and renewal surveys. The survey follow the IMO harmonized system and certification (HSSC).

Marpol Annex VI Controls The Following Six Sources Of Air Pollution From Ships;

1. Emission of Ozone Depleting Substances;

2. Nitrogen Oxide (NOx) emission from Diesel Engines;

3. Sulphur Oxide Emission;

4. Emission Of volatile Organic Compounds;

5. The Incineration of shipboard wastes;

6. Fuel Oil Quality.

1. Ozone depleting substances:-

Marpol Annex VI prohibits delibrate emission of ozone depleting substances.

Chlorofluoro Carbons (CFCs) Like R-11, R-12, & R-502 are used in referigration and air conditioning system, Halons (Bromo fluoro Carbons) like halon-1211, Hanlon-1301, & Halon-2402 used extensively for fire fighting and explosion prevention. Indestructible CFCs remain in troposphere, When these CFC gases migrates from Troposphere to the stratosphere, the are broken down by photolysis to release chlorine atoms. These chlorine atoms catalytically destroys ozone, the gas which acts as a filter of UV light from the sun. Ozone absorbs UV radiation without itself being consumed result is to convert UV light into heat.

IMAGESOFreactions

Thus ozone gas is getting depleted in a chain reaction by the O-Atom. New installations containing Ozone depleting substances shall be prohibited on all ships, Except those contianing hydro-Choloro-Fluoro Carbon (HCFCs), like R-22 are permitted untill 01 january 2020. Increase UV light on earth as a result of Ozone depletion will, amongst other possible consequences, cause skin cancer, interfere with immune system, harm aquatic system and crops.

Further more, CFCs along with other "Green House Gases" inhibit the release of heat from the earth, thereby contributing global warming. Scientists predict that if contributing to global warming. scientists predict that if the average global temperature continues to increase, the mean sea level will rise due to melting of ice from poles, with catastrophic flooding in certain low lying areas of the world.

The CFCs are characterised under the Montreal protocol according to the extent to which they damage the Ozone layer. The most damaging CFC is given as "Ozone Depletion Potential(ODP)" of 1 and "Global Warming Potential (GWP)" of 1 & "Green house potential (GP)" of 3300, with R-11 as the base, & Others are given Values compared to base 1 of R-11

TABLEOFREFIGERANT

2. NOx control:-

Technical code: - the code will applied when a diesel engine with power output of 138 and above installed on a ship who skill was laid on or after 1st January 2004 any diesel engine with power output of 138 and above which has undergone a major conversion on or after 1st January 2002 which are used solely for emergency.

Major conversion means the maximum continuous rating of the engine is increased by more than 10% over the engine is replaced by a new Indian built on or after 1st January 2000.

General exceptions: - emergency diesel engine life board engine or any other engine installed in equipment in landed solely for emergency use do not have to comply with regulation on NOX control Marpol Annexe VI requires all diesel engine with a power output of more than 130kw be tested and issued with an engine International Air pollution prevention (IAPP) certificate and an appropriate NOx technical file the Administration may allowed exclusion from the application of this regulation to any engine which is installed on a ship constructed or which undergoes a major conversion before 19th may 2005 provided that the ship is solely engaged in domestic services.

Effects of NOx: -

NOx emission and N2 and O2 lead to petrol chemical smog and acid rain and depletion of Ozone layer. Smog and acid rain are more prominent on land.

Causes of NOX formation: -

The nitrogen present in the combustion air and the organic nitrogen present in the fuel combines with the oxygen at a high temperature to form oxides of Nitrogen.

Does higher the combustion temperature that is high compression ratio high pitch pressure high rate of fuel delivery higher the residence high temperature that is stored the speed of Indian Higher the knocks formation yellowish brownish colour of the exhaust plume indicates high concentration of NOX it may be noted on a Global scale search quantity of NOX produced naturally by bacterial and volcanic action and by lightning which for outfit those generated by man's activities.

3. SOx Control:-

Sulphur content of fuel oil on board ship should not exceed 4.5% m/m on any part of the world and should have documentary evidence to prove this (Analyst Report). In SOx emission Conrol Area(SECA), sulphur content of fuel not to exceed 1.5% m/m unless exhaust gas cleaning system or equivalent used. Before entering SECA change over from HFO to Diesel has to be completed. Baltic Sea will be the first of this kind and will enter in force by may 2006. Water washing the exhaust with abatement technology is also approved if the SOx could be reduced to 6g/KWh.

Scubbers can wash out sulphur from exhaust gas but it will take up valuable space and possibly a health hazard as cooler of exhaust gas may descant forwards deck and poison the crew. Moreover sea water can wash out particulate matter in addition to SOx, which are harmful to marine life. To extract sulphur and H2SO4 from scrubber output water which can be marketed.

4. Volatile Organic Matter:-

A vapour emission control (VEC) system is only required to be used where local regulation require the discharge of volatile organic compounfs to be controlled.

The regulation controls the standard the VEC system must comply with and actions required by countries which require VEC system to be used.

This regulation shall only apply to gas carriers when the type of loading containment syste, allow safe retention of non-methane VOCs on board, or thier safe return to shore.

5. Ship Board Incineration:-

The regulations do not require that an incinerator is fitted or that waste must be incinerated. The regulation only control incinerator emission standards when an incinerator is installed on or after the 1st jan 2000 are to be approved in accordance with IMO standards. The Incineration of certain Material, that could result in toxic emission will be prohibited, this includes:

i) cargo residues from Marpol Annex I, II,& III and any related contaminated Packaging.

ii) Polychlorinated bipheonyl's (PCB's)

iii) Garbage Containing Traces of heavy metal

iv) Refined Petrolium Products.

Other aspects of incineration control already exist in Marpol 73/78 annex V and the associated guidelines for the implementation of that annex.

6. Fuel oil Quality:-

Gaseous and condensed hydrocarbons and particulate matters are a result of incomplete combustion and/or poor quality. Poor quality is to be avoided to obviate release of such matters.

By using exhaust gas filter or wet electrostatic precipitator in which particles are ionised to make them stick to the electrode and the dust eventually wash out. "Electro-cyclone system of Wartsila which combines the advantages of cyclone and electrostatic precipitators, reduces particle emission by more than 60% with the engine running on heavy fuel oil.

Certificates and Other Documents Which are to be retained on board ships with the annex in force:-

i) BDN for three years.

ii) EIAPP certificate (or statement of compliance), Technical file & IAPP certificate.

iii) Record book of engine parameters.

iv) Operational Manual for onboard direct measurement and monitoring methods.

v) Operation manual for Vapour collection system.

vi) Operational manual for shipboard incinerator.

vii) Logbook

viii) EEDI

ix) SEEMP

NOx Technical File

NOx technical file consist of following details:-

1. Components settings and operating values of the engine which influences its NOx emission.

2. Full range of allowable adjustments or alternative for the components of the engine.

3. Full record of the relevant engine's performance, including engines rated speed and rated power.

4. On board NOx verification procedure.

5. Emission test report.

6. Designation and restriction for an engine which is a member of engine group or engine family.

7. Specification of spare parts/components which, when used in the engine, according to those specifications, will result in continuous compliance of the engine with the NOx emission limits.

8. EIAPP certificate or statement of voluntary compliance

Prevention of Air Pollution from Ships

MARPOL Annex VI, as first adopted in 1997, and entered into force 19 May 2005, limits the main air pollutants contained in ships exhaust gas, including sulphur oxides (SOx) and nitrous oxides (NOx), and prohibits deliberate emissions of ozone depleting substances. MARPOL Annex VI also regulates shipboard incineration, and the emissions of volatile organic compounds from tankers. The revised Annex VI entered into force on I July 2010, sets limits on sulphur oxide and nitrogen oxide emissions from ship exhausts as well as particulate matter and prohibits deliberate emissions of ozone depleting substances, such as hydro-chlorofluorocarbons. Stricter standards are set for Emission Control Areas designated by IMO (Baltic Sea, North Sea and North America).

The main changes to MARPOL Annex VI are a progressive reduction globally in emissions of SOx, NOx and particulate matter and the introduction of emission control areas (ECAs) to reduce emissions of those air pollutants further in designated sea areas. Under the revised MARPOL Annex VI, the global Sulphur cap is reduced initially to 1.50% (from the current 4.50%), effective from 01 January 2012; then progressively to 0.50 %, effective from 01 January 2020, subject to a feasibility review to be completed no later than 2018. The limits applicable in ECAS for SOx and particulate matter were reduced to 1.00%, beginning on 01 July 2010 (from the original 1.50%); being further reduced to 0.10%, effective from 01 January 2015.

Progressive reductions in NOx emissions from marine diesel engines installed on ships are also included, with a "Tier II" emission limit for engines installed on or after I January 2011; then with a more stringent Tier III" emission limit for engines installed on or after I January 2016 operating in ECAS. Marine diesel engines installed on or after 1 January 1990 but prior to 01 January 2000 are required to comply with "Tier I emission limits, if an approved method for that engine has been certified by an Administration.

The revised NOx Technical Code 2008 includes a new chapter based on the agreed approach for regulation of existing (pre-2000) engines established in MARPOL Annex VI, provisions for a direct measurement and monitoring method, a certification procedure for existing engines, and test cycles to be applied to Tier II and Tier III engines.

Revisions to the regulations for ozone-depleting substances, volatile organic compounds, shipboard incineration, reception facilities, and fuel oil quality have been made with regulations on fuel oil availability added.

The revised measures are expected to have a significant beneficial impact on the atmospheric environment and on human health, particularly for those people living in port cities and coastal communities.

NOx Technical Code

The Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines adopted by IMO. This document covers engine testing, certification and onboard verification procedures to demonstrate continuing compliance with the applicable NOx emissions limits.

New NOx limits The revised NOx regulations contain a three-tier approach as follows:

IMAGE

It should be noted that the Tier III limits cannot be achieved without additional means, such as Selective Catalytic Reduction (SCR) and Water Injection.

IMAGE

The main changes to MARPOL, Annex VI are a progressive reduction globally in emissions of SOx, NOX and particulate matter and the introduction of emission control areas (ECAs) to reduce emissions of those air pollutants further in designated sea areas NOx Emission Tier II standard will be enforced from I Jan 2016 in Emission Control Areas (ECA) as per the latest MEPC 66 meeting.

What in NOx Tier III?

Progressive reductions in NOx emissions from marine diesel engines installed on ships is included in MARPOL Annex VI, with a "Tier II" emission limit for engines installed on of after January 2011. NOx "Tier II" is a more stringent emission limit for engines installed on or after I January 2016 operating in ECAs.

Marine diesel engines installed on or after 1 January 1990 but prior to 1 January 2000 are required to comply with "Tier I" emission limits, if an approved method for that engine has been certified by an Administration.

NOx Tier III emission standards are 80% less than NOx Tier I emission standards. The emission value for a diesel engine is to be determined in accordance with the NOx Technical Code 2008 in the case of Tier II and Tier III limits.

As per Marpol Annex VI Tier III limits are :

NOx Emission:

TIERS | Duration | RPM n<130 | 130<n<1999 | n>1999 |

TIER-I | From 01-Jan-2000 to 31-Dec-2010 | 17 gm/kw.hr | 45xn^-0.2 gm/kw.hr | 9.8 gm/kw.hr |

TIER II | From 01-Jan-2010 to 31-Dec-2015 | 14.36 gm/kw.hr | 44xn^-0.23 gm/kw.hr | 7.66 gm/kw.hr |

TIER-III | After 01-Jan-2016 | 3.4 gm/kw.hr | 9xn^-0.2gm/kw.hr | 1.96 gm/kw.hr |

NOx Reduction Methods

To comply with this Tier III requirements ships shall have to be installed or retrofitted with equipment/systems which can reduce NOx below Tier III standards. Mentioned below are seven technologies available to meet this criteria.

1. Selective Catalytic Reduction (SCR): In this system urea or ammonia is injected in the exhaust gas before passing it through a unit, which consists of special catalyst layer, at a temperature between 300 and 400 Deg C. Chemical reaction between Urea/ammonia and NOx in exhaust gases reduces NOx (NO and NO2) to N2. SCR unit is installed between the exhaust manifold/receiver and the turbucharger.

High efficiency turbocharger is required for this system as there is pressure drop across SCR Reactor, Engine load should be 40% and above, as NOx is reduced to N2 within specific temperature window ( 300-400 Deg C).

If temperature is above 400 Deg C, ammonia will burn rather than reacting with NOx which will lead the system to be ineffective. If the temperature is below 270 Deg C. the reaction rate will be low and the ammonium sulphates formed will destroy the catalyst.

➤Some B&W engine uses DeNOx or SiNOX system using SCR technology.

➤Some Wartsila engines also has NOR (NOx Reduction) system that uses SCR technology.

More than 90% reduction is achieved by using SCR technology to comply with Tier III emission standards.

2. Exhaust Gas Recirculation (EGR): In this technology, part of the exhaust gas after turbocharger is recirculated to scavenge receiver after passing it through the scrubber ( exhaust gas washing ) unit. Around 50-60% NOX reduction from tier I is claimed by making use of EGR. However discharge of cleaning water requires treatment like purification and separating exhaust gas cleaning sludge. As some countries are against discharge of this water, re-using this water poses corrosion problem.

NOx reduction takes place due to reduction in excess air (oxygen content) used for combustion addition of CO2, and water vapour reduces peak temperatures as both have higher specific heat than air. EGR system along with combination of one of the technologies such as altered (delayed) injection method, new design fuel valve, common rail injection principle, electronic engines, Scavenge Air Moisturizing can he used to comply with Tier III standards.

3. Scavenge Air Moisturizing : Air from the turbocharger after passing through the compressor, has high temperature Seawater is injected to this high temperature air for cooling and making it saturated. Distillation process makes it possible to use sea water instead of fresh water. Humidification of air is controlled by maintaining scavenge air temperature between 60-70 Deg C. Water in saturated air reduces the peak temperature as water has higher heat carrying capacity than air.

Around 60% NOx reduction is achieved by this method. By using combination of other technologies such as EGR with Scavenge Air Moisturizing, NOx Tier III standards can be achieved.

4. Miller Cycle : By making use of Miller cycle in 4-Stroke engines along with high efficiency turbocharger, that is, early closing of inlet valves before BDC, causes expansion and cooling of intake air which reduces NOx production. This NOx reduction method will require two turbochargers (2-Stage turbocharging). This method along with Direct Water injection (DWI) Principle and other methods such us fuel water emulsion can bring NOx well below Tier III standards.

5. Use of Low Pressure Gas Engines: New marine engines using low pressure LNG as marine fuel will have greater importance in meeting Tier III standards. Wartsila has developed 2-stroke DF technology engine which makes use of low pressure LNG as fuel. It is based on lean-bun principle (relatively high air/fuel ratio) in which the pre-mixed air/fuel charge is ignited by pilot fuel. One of the most important aspects of this engine is that the emission are below NOx Tier limit, and this is achieved without use of exhaust gas treatment system.

6. CSNOx: Ecospec have developed a system known as CSNOx which uses fresh water or seawater to pass through Ultra Low Frequency Electrolysis system. This treated water is further mixed with to react with the exhaust gas to reduce NOx content. The system reduces CO2, SOx and NOx in one compact equipment. This technology along with other NOx reducing methods mentioned above can be used for compliance with Tier III standards. CSNOx has an advantage of achieving high efficiency with low maintenance and power consumption.

7. Combination: Combination of Technologies having one or more combinations such as electronic engines with variable fuel timings, LNG as fuel or Direct water injection or Fuel in water emulsions etc with other NOx reducing methods can be used to comply with Tier III emission standards. These mentioned combination may or may not require exhaust gas scrubber to comply with Tier III norms.

Special Areas as per MARPOL

Annex -I

(1) The Mediterranean Sea

(2) The Baltic Sea

(3) The Black Sea

(4) The Red Sea

(5) The Gulfs area

(6) The Gulf of Aden area

(7) The Antarctic area

(8) The North West European waters

(9) Oman area of Arabian Sea

(10) Southern South African water

Annex-II

Antarctic Area

Annex-IV

Baltic sea

Annex-V

(1) The Mediterranean Sea

(2) The Baltic Sea

(3) The Black Sea

(4) The Red Sea

(5) The Gulfs area

(6) The North Sea area

(7) The Antarctic area

(8) The Wider Caribbean region and gulf of maxico

Annex-VI

(1) Baltic sea

(2) North sea

(3) North American waters

(4) U.S Caribbean sea

Entries of ORB

Entries of ORB with codes and who all sing on it?

➤Usage of code C.11: Collection of oil residues (sludge).

➤Usage of code C.12: Disposal or Transfer of oil residues (sludge).

➤Usage of code D: Non-automatic starting of discharge overboard, transfer or disposal otherwise of bilge water which has accumulated in machinery spaces.

➤Usage of code E: Automatic starting of discharge overboard, transfer or disposal otherwise of bilge water which has accumulated in machinery spaces.

➤Usage of code F: Condition of oil filtering equipment.

➤Usage of code G: Accidental or other exceptional discharges of oil.

➤Usage of code H: Bunkering of fuel or bulk lubricating oil.

➤Usage of code I: Additional operational procedures and general remarks.

This guidance only includes sections C to I.

1. Operations should be recorded in chronological order as they have been executed on board.

2. Dates should be entered in dd/mm/yyyy format, e.g. 16-MAR-2009.

3. Incineration or landing ashore of oily garbage and used filters should be recorded in the Garbage Record Book only.

4. All Entries are to be made and signed by the officer or officers in charge of the operations concerned and each completed page shall be signed by the master of the ship.

5. Do not leave any full lines empty between successive entries.

6. If a wrong entry has been recorded in the Oil Record Book (ORB), it should immediately be struck through with a single line in such a way that the wrong entry is still legible. The wrong entry should be signed and dated, with the new corrected entry following.

7. Tank nomenclature should be recorded as per the format noted within the International Oil Pollution Prevention Certificate (IOPPC).

8. Recording of quantities retained in bilge water holding tanks listed under section 3.3 of the IOPPC is voluntary and not required by the Convention.

9. The recording of general maintenance of items pertaining to the OWS remains voluntary and is not required to be recorded in the ORB.

Items in SOPEP

SOPEP contains the following things:

➤The action plan contains the duty of each crew member at the time of the spill, including emergency muster and actions.

The general information about the ship and the owner of the ship etc.

➤Steps and procedure to contain the discharge of oil into the sea using SOPEP equipment.

➤The inventory of the SOPEP material provided for pollution prevention such as oil absorbent pads, sawdust bags, booms etc.

Onboard reporting procedure and requirement in case of an oil spill.

➤Authorities to contact.

➤Drawing of various fuel lines, along with other oil lines on board vessel with the positioning of vents, save all trays etc.

➤The general arrangement of the ship including the location of all the oil tanks with capacity, content etc.

➤The location of the SOPEP locker and contents of the locker with a list of inventory,

➤Guidance to keep the records of the pollution incident (for liability, compensation and insurance purpose)

➤Material for Reference from essential organisations (guidelines issued by ICS, OCIMF, SIGTTO, INTERTANKO, etc.)

➤Procedures for testing various plan described in the SOPEP.

➤Procedure to maintain the record as required by the authorities.

➤Details of when and how to review the plan.

Marpol Annex 1- Regulation 37 - Shipboard oil pollution emergency plan

1 Every oil tanker of 150 gross tonnage and above and every ship other than an oil tanker of 400 gross tonnage and above shall carry on board a shipboard oil pollution emergency plan approved by the Administration.

2 Such a plan shall be prepared based on guidelines developed by the Organization and written in the working language of the master and officers. The plan shall consist at least of:

(i) the procedure to be followed by the master or other persons having charge of the ship to report an oil pollution incident, as required in article 8 and Protocol I of the present Convention, based on the guidelines developed by the Organization;

(ii) the list of authorities or persons to be contacted in the event of an oil pollution incident;

(iii) a detailed description of the action to be taken immediately by persons on board to reduce or control the discharge of oil following the incident; and

(iv) the procedures and point of contact on the ship for coordinating shipboard action with national and local authorities in combating the pollution.

3 In the case of ships to which regulation 17 of Annex II (shipboard marine pollution emergency plan for noxious liquid substances) of the present Convention also applies, such a plan may be combined with the shipboard marine pollution emergency plan for noxious liquid substances required under regulation 17 of Annex II of the present Convention. In this case, the title of such a plan shall be ''Shipboard marine pollution emergency plan''.

4 All oil tankers of 5,000 tonnes deadweight or more shall have prompt access to computerized shore-based damage stability and residual structural strength calculation programs.

SOPEP (Ship board oil pollution emergency plan) Items list:-

a. Saw dust

b. Scupper plug

c. Sorbent pillows

d. Nitrile protective gloves

e. Quick absorbent pads

f. Brushes

g. Non-Spark Scoop

h. Non-Spark Pump

i. Weldon Pump

j. Buckets

k. Heavy duty Brooms

l. OSD (oil spill Dispersant)

m. Cotton Rags

n. Drum to collect oil 200ltr capacity.

Instantaneous Rate Of Discharge

➤Instantaneous rate of discharge of oil content means the rate of discharge of oil in litres per hour at any instant divided by the speed of the ship in knots at the same instant.

➤Instantaneous rate of discharge of oil content does not exceed 30 litres per nautical mile; provided ship is en route and more than 50 nautical miles from the nearest land;

➤Also total quantity of oil discharge into sea for ships delivered on or before 31st December 1979 is 1/15000 of total quantity of particular cargo of which the residue formed a part and 1/30000 for tankers delivered after above mentioned date.

➤for sewage which has been stored in holding tanks, or sewage originated from spaces contain living animals shall not be discharged instantaneously but at a moderate rate when ship is en route with 4 knots speed; the discharge rate shall be approved by Administration.

Comments

Post a Comment