Answer EKM Question 57

Q57. With reference to a slow speed diesel engine fitted with a single turbocharger. describe, with reasons, the possible action which could be taken to enable the main engine to be operated, If whilst on oceanic passage, a small portion of one of the impeller vanes breaks off and is impacted with the charge air cooler.

Ans: Since a portion of the impeller vanes breaks off the turbocharger shaft is now unbalanced, further operating the turbocharger will cause severe damage to the shaft and Bearings. This broken piece has impacted the air cooler, it must to taken out as it may enter the cylinder with scavenging air causing severe damage to the engine.

Procedure for Running the engine with a single turbocharger, the failure can be categorized into two sections.

The engine is fitted with a single turbocharger with an exhaust by-pass.

The engine is fitted with a single turbocharger without an exhaust by-pass.

To Cut off Damaged Turbochargers for Engine Operation

1. Engines with one turbocharger (Engines with exhaust by-pass)

Stop the engine.

Lock the turbocharger rotor.

Remove the blanking plate from the exhaust by-pass pipe.

Remove the compensator between the compressor outlet and the scavenge air duct. This reduces the suction resistance.

Run engine with 15% of MCR load and 53% speed.

2. Engines with one turbocharger (Engine without exhaust by-pass)

Stop the engine.

Remove the rotor and nozzle ring of the turbocharger.

Insert blanking plates.

Remove the compensator between the compressor outlet and the scavenge air duct. This reduces the suction resistance.

Run engine with 15% of MCR load and 53% speed.

Locking Of the Rotor:

Ans: Since a portion of the impeller vanes breaks off the turbocharger shaft is now unbalanced, further operating the turbocharger will cause severe damage to the shaft and Bearings. This broken piece has impacted the air cooler, it must to taken out as it may enter the cylinder with scavenging air causing severe damage to the engine.

Procedure for Running the engine with a single turbocharger, the failure can be categorized into two sections.

The engine is fitted with a single turbocharger with an exhaust by-pass.

The engine is fitted with a single turbocharger without an exhaust by-pass.

To Cut off Damaged Turbochargers for Engine Operation

1. Engines with one turbocharger (Engines with exhaust by-pass)

Stop the engine.

Lock the turbocharger rotor.

Remove the blanking plate from the exhaust by-pass pipe.

Remove the compensator between the compressor outlet and the scavenge air duct. This reduces the suction resistance.

Run engine with 15% of MCR load and 53% speed.

2. Engines with one turbocharger (Engine without exhaust by-pass)

Stop the engine.

Remove the rotor and nozzle ring of the turbocharger.

Insert blanking plates.

Remove the compensator between the compressor outlet and the scavenge air duct. This reduces the suction resistance.

Run engine with 15% of MCR load and 53% speed.

Locking Of the Rotor:

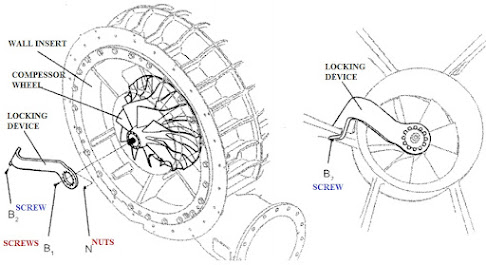

Fitting the Locking Device:

• Remove retaining nuts with screws

• Turn back screw B2 to ensure full slot on the locking device

• Position slot on the rib of wall insert

• Align hole circle of locking device with compressor wheel holes

• Fit at least 9 screws B1

• If more than 3 drill holes are used for set screw, then unscrew the corresponding number

• Tight B1 screws & B2 screw as per torque

Locking the rotor with screwed connection:

• Remove screw plug

• Fix needed studs on the casing

• Fix locking device & tighten nuts (Torque)

• Block Rotor with lock

• Secure lock with screw

Turbocharger Temporary or Permanent Repair in the event of breakdown

Related Article

Operation while a turbocharger is out of service

Comments

Post a Comment