Answer EKM Question 25

Q25. A. Sketch and show all parts of a two-stroke engine stuffing box.

B. Describe the procedure of overhauling two stroke engine stuffing box, without removing piston.

C. All safety precautions to be mentioned proper tools used for overhaul mentioned.

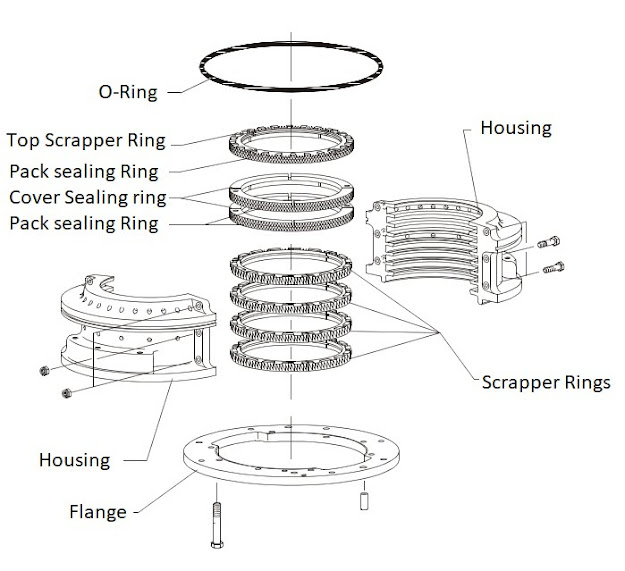

Answer:A. Sketch and show all parts of a two-stroke engine stuffing box

B. Overhaul inside the engine is carried out in the same way as outside the engine.

1. Mount two eye bolts in the stuffing box flange, and hook on two tackles.

Lift the stuffing box a little up the piston rod, and mount the worktable round the piston rod at a suitable working height.

Land the stuffing box on the worktable, and remove the tackles and eye bolts.

2. Remove the O-ring of the stuffing box. If the O-ring is intact and is to be used again, move it up the piston rod and secure it in this position, for example with tape. Remove the nuts from the stuffing box assembling bolts.

3. Take out the six bolts, and pull away one stuffing box half. Mount two eye bolts on the stuffing box half and remove it from the worktable.

4. Using a feeler gauge, measure the vertical clearance of the rings.

5. Remove the remaining stuffing box half and press all sealing rings and scraper rings down against the worktable.

6. Measure the clearance between the ring segments to determine whether replacement is necessary. Dismantle and stack the rings in the same order as when fitted in the stuffing box. Carefully clean all the ring segments. Inspect and assess the surface quality of the sealing rings. If their sliding surfaces have scratches or marks, replace the rings.

7. Check the lengths of the springs.

8. Inspect the surface of the piston rod. If small longitudinal scratches have occurred (caused by poorly adapted stuffing box rings), smooth the piston rod surface care-fully with a fine grained carborundum stone.

In the case of coarse scratches, it may prove necessary to machine-grind the surface in a workshop.

9. Clean the halves of the stuffing box housing.

10. Lubricate the piston rod (in the area where all the ring units in the stuffing box-will be positioned) with molybdenum disulphide (MoS2).

Assemble all the stuffing box ring units round the piston rod, on the worktable, in the following way:

• Place the lowermost scraper ring segments on the worktable.

• Place the spring round the segments, and hook the spring ends together.

Repeat this procedure for the remaining scraper rings.

On top of the scraper rings, assemble the two sealing ring units (each consisting of a 4-part and an 8-part ring).

Assemble the 8-part sealing ring so that the two guide pins face upwards, place the spring round the segments and, hook the spring ends together.

Assemble the 4-part sealing ring above the 8-part sealing ring. Push the two rings together in such a manner that the guide pins in the lower sealing ring engage with the two holes in the upper sealing ring. Finally, assemble the uppermost ring unit (consisting of a 4-part scraper ring and an 8-part sealing ring).

11. Use the stuffing box half on the worktable to adjust the height of all the assembled ring units on the piston rod until the ring units are opposite the corresponding grooves in the stuffing box housing. Subsequently, push the stuffing box half into con-tact with the piston rod, round the ring units.

Note! If the stuffing box is assembled inside the engine, place two pieces of plywood of the same thickness as the flange on the worktable, to ease the assembling.

12. Check the ring clearance again.

Then place the other half of the stuffing box housing on the worktable, pushing it into place round the rings.

Mount and tighten up the fitted bolts to the torque specified. Mount the O-ring in the stuffing box groove.

13. Mount eye bolts and wire ropes, and lift the stuffing box a little.

Remove the worktable and lower the stuffing box until it rests against the distance pieces on the piston rod foot. Remove wire ropes and screws.

Mounting:

1. In connection with mounting of the piston, only the innermost flange screws are to be mounted and tightened.

After overhauling the stuffing box inside the engine, assemble the stuffing box halves on top of the four screws. Mount the two long screws from the worktable in the stuffing box. Turn down the short screws so that the stuffing box lands on the flange.

2. Turn the piston upwards until the stuffing box is in place in the cylinder frame.

Note! Make sure that the two guide pins in the flange enter the guide holes in the bottom of the cylinder frame.

3. Mount two screws in the flange through the holes in the worktable.

4. Remove the long screws from the stuffing box and mount them in the worktable.

Remove the worktable from the piston rod.

5. Mount and tighten all the inner and outer screws for the stuffing box.

6. Remove the protecting rubber cover from the piston rod/crosshead. Smear the piston rod with molybdenum disulphide. Then turn the crankshaft a couple of revolutions.

Start up the engine and keep it running for about fifteen minutes at a number of revolutions corresponding to very slow or idle speed.

Then stop the engine and inspect the piston rod and stuffing box.

Checks:

Uppermost scraper ring and sealing rings

a. Clearance at ring ends (scraper ring).

b. Total clearance (scraper ring).

c. Clearance at ring ends (sealing rings).

d. Total clearance (sealing rings).

Lowermost scraper rings

a. Clearance at ring ends.

b. Total clearance.

C. Safety Precautions:

Stopped engine

Block the starting mechanism

Shut off starting air supply

Engage turning gear

Shut off cooling water

Shut off fuel oil

Shut off lubricating oil

Lock turbocharger rotors

1. Mount two eye bolts in the stuffing box flange, and hook on two tackles.

Lift the stuffing box a little up the piston rod, and mount the worktable round the piston rod at a suitable working height.

Land the stuffing box on the worktable, and remove the tackles and eye bolts.

2. Remove the O-ring of the stuffing box. If the O-ring is intact and is to be used again, move it up the piston rod and secure it in this position, for example with tape. Remove the nuts from the stuffing box assembling bolts.

3. Take out the six bolts, and pull away one stuffing box half. Mount two eye bolts on the stuffing box half and remove it from the worktable.

4. Using a feeler gauge, measure the vertical clearance of the rings.

5. Remove the remaining stuffing box half and press all sealing rings and scraper rings down against the worktable.

6. Measure the clearance between the ring segments to determine whether replacement is necessary. Dismantle and stack the rings in the same order as when fitted in the stuffing box. Carefully clean all the ring segments. Inspect and assess the surface quality of the sealing rings. If their sliding surfaces have scratches or marks, replace the rings.

7. Check the lengths of the springs.

8. Inspect the surface of the piston rod. If small longitudinal scratches have occurred (caused by poorly adapted stuffing box rings), smooth the piston rod surface care-fully with a fine grained carborundum stone.

In the case of coarse scratches, it may prove necessary to machine-grind the surface in a workshop.

9. Clean the halves of the stuffing box housing.

10. Lubricate the piston rod (in the area where all the ring units in the stuffing box-will be positioned) with molybdenum disulphide (MoS2).

Assemble all the stuffing box ring units round the piston rod, on the worktable, in the following way:

• Place the lowermost scraper ring segments on the worktable.

• Place the spring round the segments, and hook the spring ends together.

Repeat this procedure for the remaining scraper rings.

On top of the scraper rings, assemble the two sealing ring units (each consisting of a 4-part and an 8-part ring).

Assemble the 8-part sealing ring so that the two guide pins face upwards, place the spring round the segments and, hook the spring ends together.

Assemble the 4-part sealing ring above the 8-part sealing ring. Push the two rings together in such a manner that the guide pins in the lower sealing ring engage with the two holes in the upper sealing ring. Finally, assemble the uppermost ring unit (consisting of a 4-part scraper ring and an 8-part sealing ring).

11. Use the stuffing box half on the worktable to adjust the height of all the assembled ring units on the piston rod until the ring units are opposite the corresponding grooves in the stuffing box housing. Subsequently, push the stuffing box half into con-tact with the piston rod, round the ring units.

Note! If the stuffing box is assembled inside the engine, place two pieces of plywood of the same thickness as the flange on the worktable, to ease the assembling.

12. Check the ring clearance again.

Then place the other half of the stuffing box housing on the worktable, pushing it into place round the rings.

Mount and tighten up the fitted bolts to the torque specified. Mount the O-ring in the stuffing box groove.

13. Mount eye bolts and wire ropes, and lift the stuffing box a little.

Remove the worktable and lower the stuffing box until it rests against the distance pieces on the piston rod foot. Remove wire ropes and screws.

Mounting:

1. In connection with mounting of the piston, only the innermost flange screws are to be mounted and tightened.

After overhauling the stuffing box inside the engine, assemble the stuffing box halves on top of the four screws. Mount the two long screws from the worktable in the stuffing box. Turn down the short screws so that the stuffing box lands on the flange.

2. Turn the piston upwards until the stuffing box is in place in the cylinder frame.

Note! Make sure that the two guide pins in the flange enter the guide holes in the bottom of the cylinder frame.

3. Mount two screws in the flange through the holes in the worktable.

4. Remove the long screws from the stuffing box and mount them in the worktable.

Remove the worktable from the piston rod.

5. Mount and tighten all the inner and outer screws for the stuffing box.

6. Remove the protecting rubber cover from the piston rod/crosshead. Smear the piston rod with molybdenum disulphide. Then turn the crankshaft a couple of revolutions.

Start up the engine and keep it running for about fifteen minutes at a number of revolutions corresponding to very slow or idle speed.

Then stop the engine and inspect the piston rod and stuffing box.

Checks:

Uppermost scraper ring and sealing rings

a. Clearance at ring ends (scraper ring).

b. Total clearance (scraper ring).

c. Clearance at ring ends (sealing rings).

d. Total clearance (sealing rings).

Lowermost scraper rings

a. Clearance at ring ends.

b. Total clearance.

C. Safety Precautions:

Stopped engine

Block the starting mechanism

Shut off starting air supply

Engage turning gear

Shut off cooling water

Shut off fuel oil

Shut off lubricating oil

Lock turbocharger rotors

Comments

Post a Comment