Answer EKM Question 33

Q33.

Explain the functional and constructional diffidence between the

Torsional and Axial vibration dampers with the help of neat sketches,

Explain the function of the side and Top bracing of the main engine.

Answer: Axial Vibration:

(a) Axial (longitudinal) vibrations are the result of the pulsing hydrodynamic forces induced on the propeller and dynamic longitudinal deformations of the crankshaft. When a crank throw is loaded by gas pressure and mass forces through a connecting rod mechanism, the arms of the crank throw deflect in the axial direction of the crankshaft, exciting axial vibrations.

(b) These vibrations may cause the engine crankshaft to tail with increasing frequency.

The propulsion system is connected to the ship's hull through a thrust bearing. Therefore the axial vibrations are transferred to different regions of the ship's hull structure through a thrust bearing and axial damper to the ship's double bottom.

Axial vibration dampers:

(a) The Axial damper is fitted on the forward side of the, crankshaft of the engine to dampen the shaft generated axial vibration i.e. oscillation of the shaft in forward and aft directions, parallel to the shaft horizontal line.

(b) Axial dampers consist of a damping piston integrated to the crankshaft and placed near the last main bearing girder, inside a stationary cylindrical casing.

(c) The casing is filled with system oil on both side of piston supplied via non-return valve.

(d) The piston on either side of the oil is sealed by O-rings with garter springs, hence forward and aft side of the piston acts as different chambers.

(e) The oil in one side will move to another side if the piston is moved due to axial movement, through a needle valve which provides the dampening effect.

(f) The casing is provided with high temperature alarm and pressure monitoring alarms located on both sides of damping flanges. LO level on either side is also monitored via sight glass or alarm.

(a) Axial (longitudinal) vibrations are the result of the pulsing hydrodynamic forces induced on the propeller and dynamic longitudinal deformations of the crankshaft. When a crank throw is loaded by gas pressure and mass forces through a connecting rod mechanism, the arms of the crank throw deflect in the axial direction of the crankshaft, exciting axial vibrations.

(b) These vibrations may cause the engine crankshaft to tail with increasing frequency.

The propulsion system is connected to the ship's hull through a thrust bearing. Therefore the axial vibrations are transferred to different regions of the ship's hull structure through a thrust bearing and axial damper to the ship's double bottom.

Axial vibration dampers:

(a) The Axial damper is fitted on the forward side of the, crankshaft of the engine to dampen the shaft generated axial vibration i.e. oscillation of the shaft in forward and aft directions, parallel to the shaft horizontal line.

(b) Axial dampers consist of a damping piston integrated to the crankshaft and placed near the last main bearing girder, inside a stationary cylindrical casing.

(c) The casing is filled with system oil on both side of piston supplied via non-return valve.

(d) The piston on either side of the oil is sealed by O-rings with garter springs, hence forward and aft side of the piston acts as different chambers.

(e) The oil in one side will move to another side if the piston is moved due to axial movement, through a needle valve which provides the dampening effect.

(f) The casing is provided with high temperature alarm and pressure monitoring alarms located on both sides of damping flanges. LO level on either side is also monitored via sight glass or alarm.

Torsional vibration:

(a) The gas pressure of the engine acts through the connecting rod mechanism with a varying torque on each crank throw, exciting torsional vibration in the system with different frequencies.

(b) Torsional Vibration is a twisting phenomenon in the crankshaft which spreads from one end to other due to uneven torque pulses aiming from different units pistons.

(c) Torsional Vibration occurs in the crankshaft of the engine mainly because of the tangential forces acting on the crankshaft when rotating at some RPM.

Torsional vibration damper coupling:

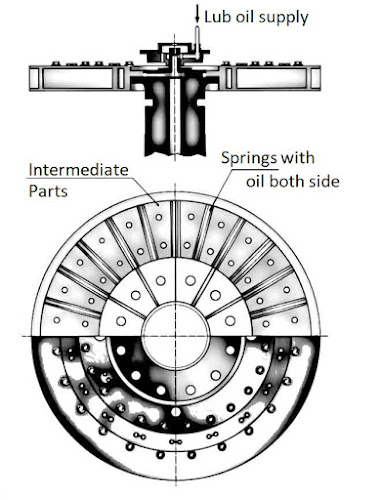

(a)

The radially arranged steel springs are clamped at their outer ends and

are engaged in the grooves of the inner star. Chambers A and B, which

are filled with engine oil, are created between the spring packs,

intermediate pieces and the inner star.(a) The gas pressure of the engine acts through the connecting rod mechanism with a varying torque on each crank throw, exciting torsional vibration in the system with different frequencies.

(b) Torsional Vibration is a twisting phenomenon in the crankshaft which spreads from one end to other due to uneven torque pulses aiming from different units pistons.

(c) Torsional Vibration occurs in the crankshaft of the engine mainly because of the tangential forces acting on the crankshaft when rotating at some RPM.

Torsional vibration damper coupling:

(b) Through the oscillation of the outer part in relation to the inners the springs are bended. This movement forces the oil to flow from chamber A to chamber B through designed damping gap.

(c) Depending on the size of this damping gap the flow is more or less restricted, thus creating different rates of torsional hydrodynamic damping.

(d) The Damper design is based on the hydrodynamic principal of damping. As a result, the damping factor stays constant over the product's lifetime because the damper is not affected by wear.

(e) In case of dampers for two-stroke engines fine tuning of the damping factor can be adjusted in the field.

Explain the function of the side and Top bracing of the main engine:

(a) These braces are fitted at the side and top of the engine in order to stiffen the upper part of the engine, and to resist the twisting on the engine imposed by the cross-head guide forces. The braces are intended to be fitted in pairs (or three for the larger engines) to one side of the engine only, usually the exhaust side, but the camshaft side is an acceptable,alternative.

(b) By Introducing this bracing, the stiffness of the engine is increased to ship attachment, thus increasing the natural frequency of the engine and the ship structure. Hence resonance of the engine structure will not occur within the normal operating range of the engine.

(c) The bracing can be either the standard mechanical friction, or hydraulic bracing when larger hull deflections can occur such as with tankers.

Comments

Post a Comment