Answer EKM Question 37

Q37. With reference to main engine turbocharger;

A. Explain why cleanliness throughout the turbochargers system is critical to engine performance?

B. Describe in-service cleaning procedure for gas and air sides of a turbocharger indicating safety precautions to be observed?Answer:

A. The

exhaust gas from heavy fuel oil during combustion contains particles

which attach to every part of the exhaust gas system. In the

turbocharger these particles stick to the turbine blades and nozzle

ring, forming a layer of dirt which reduces the turbine area and causes a

drop in efficiency. To limit this effect, the turbine has to be cleaned

during operation.

Getting the cleaning interval right for 4-stroke

engines is bit difficult. If washing is carried not too often the

cleaning results will the good, but the thermal cycles increase. This

causes material stress and may impact component durability. Especially

if the washing temperature is too high. Thermal stress can cause

cracking; the more thermal cycles, the faster the cracks develop and

propagate.

If the intervals between washing are too long more dirt will build up, causing a drop in turbocharger efficiency, blockage and an increase in the exhaust gas temperature. The layer of dirt can also harden. If this happens it can only be removed by mechanical cleaning of the turbine-side parts.

Too-frequent washing results in a loss of availability due to the necessary load reductions, while worn out parts have to be replaced more often; too-long intervals between washing also lead to a loss of availability due to the unscheduled downtime for mechanical cleaning, and then there's the cost of the work itself.

Watching some key operating parameters - turbocharger speed (rpm), exhaust gas temperature directly before the turbine and air outlet pressure after the compressor - and observing the trend can be helpful in deciding the washing frequency.

With the documented information available for example photos of the nozzle ring and turbine blade, the operator is in a better position to judge whether the cleaning interval should be longer or shorter.

Soot Blowing: The turbocharger performance will get affected if the exhaust passage after the turbocharger is in foul condition (exhaust trunk and economizer). It may lead to surging or even breakage of turbine blades. Therefore it is recommended to soot blow the exhaust gas boiler tubes on daily basis.

If the intervals between washing are too long more dirt will build up, causing a drop in turbocharger efficiency, blockage and an increase in the exhaust gas temperature. The layer of dirt can also harden. If this happens it can only be removed by mechanical cleaning of the turbine-side parts.

Too-frequent washing results in a loss of availability due to the necessary load reductions, while worn out parts have to be replaced more often; too-long intervals between washing also lead to a loss of availability due to the unscheduled downtime for mechanical cleaning, and then there's the cost of the work itself.

Watching some key operating parameters - turbocharger speed (rpm), exhaust gas temperature directly before the turbine and air outlet pressure after the compressor - and observing the trend can be helpful in deciding the washing frequency.

With the documented information available for example photos of the nozzle ring and turbine blade, the operator is in a better position to judge whether the cleaning interval should be longer or shorter.

Soot Blowing: The turbocharger performance will get affected if the exhaust passage after the turbocharger is in foul condition (exhaust trunk and economizer). It may lead to surging or even breakage of turbine blades. Therefore it is recommended to soot blow the exhaust gas boiler tubes on daily basis.

B. Turbocharger cleaning and washing.

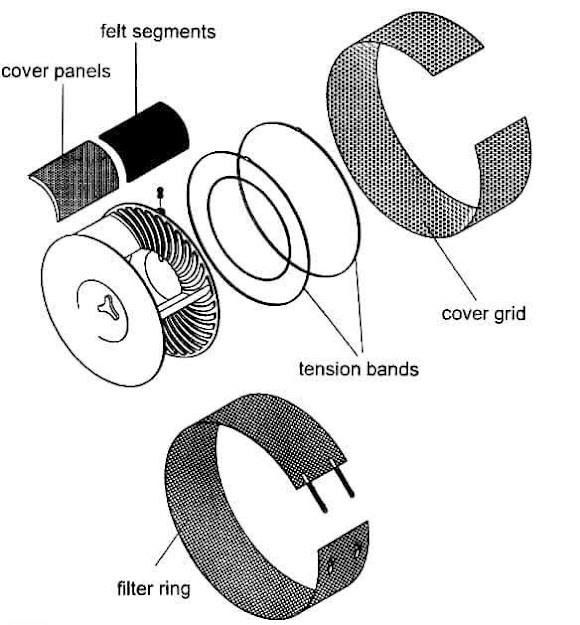

1. Cleaning the filter silencer

1.1 Washing the filter ring:- To ensure perfect operation during water washing it is advisable to replace the filter ring. Wash or replace the filter ring every 500 service hours. The filter ring is not to be washed more than 5 times.

(a) Rinse filter ring with water (up to 40 deg. cel.) using fine washing powder or, if very dirty, soak it and squeeze out carefully. Rinse in cold water. Avoid high mechanical stress(wringing, strong water jet).

(b) Allow the filter ring to dry completely before assembling.

1.1 Washing the filter ring:- To ensure perfect operation during water washing it is advisable to replace the filter ring. Wash or replace the filter ring every 500 service hours. The filter ring is not to be washed more than 5 times.

(a) Rinse filter ring with water (up to 40 deg. cel.) using fine washing powder or, if very dirty, soak it and squeeze out carefully. Rinse in cold water. Avoid high mechanical stress(wringing, strong water jet).

(b) Allow the filter ring to dry completely before assembling.

.1.2 Cleaning the silencer:-

During cleaning take care that the felt segment do not get wet.

(a) Loosen the tension bands and withdraw cover grid

(b) Withdraw the cover panels, bend them upwards and remove the felt segments.

(c) Remove dirt with a cloth, a soft brush or compressed air.

(d) Have heavily soiled felt segments replaced.

Damaged tension bands must be replaced with new ones.

During cleaning take care that the felt segment do not get wet.

(a) Loosen the tension bands and withdraw cover grid

(b) Withdraw the cover panels, bend them upwards and remove the felt segments.

(c) Remove dirt with a cloth, a soft brush or compressed air.

(d) Have heavily soiled felt segments replaced.

Damaged tension bands must be replaced with new ones.

2. Cleaning the compressor during operation.

Compressor

Compressor pollution depends on condition of the incoming air. The filters themselves are not capable of removing fine particles of soot or oil vapour, making it very important to seal leaking exhaust pipes and prevent oil losses.

Besides affectıng the efficiency, the layer of soot on the compressor contains sulphur, which has a corrosive effect on the aluminium alloy and can lead to a considerable reduction In the fatigue resistance of the inducer and compressor wheels.

Chemical aids (i.e. solvents) are not necessary for cleaning during operation. The water injection method is based on the mechanical effect of impinging droplets of water. The water has to be injected with the turbocharger running at the highest possible speed. If solvents were to be used, the speed would have to be lower and the solvent injected for a longer time to have any effect.

Cleaning the compressor

The proposed cleaning method, carried out periodically, will prevent a thick layer of dirt from forming. A thick layer of dirt can cause a drop in efficiency and increased unbalance on the compressor side of the turbocharger, which could influence the lifetime of the bearings. The cleaning interval will depend on the environmental condition and on the installed air filter. The compressor wheel of the turbocharger can be cleaned during operation by spraying water into the air inlet casing. The dirt layer is removed by the impact of the injected water. Since the liquid does not act as a solvent there is no need to add chemicals. The use of salt-water is not allowed, as this would cause corrosion of the aluminium compressor wheel and the engine. Water is injected from a water vessel that holds the required quantity of water.

Water is injected before the compressor wheel via an injection pipe fitted in the filter silencer or the suction branch in order to clean the compressor stage in operation. The water does not act as a solvent in the process, but the deposit is removed by mechanical impact of the drops.

Compressor

Compressor pollution depends on condition of the incoming air. The filters themselves are not capable of removing fine particles of soot or oil vapour, making it very important to seal leaking exhaust pipes and prevent oil losses.

Besides affectıng the efficiency, the layer of soot on the compressor contains sulphur, which has a corrosive effect on the aluminium alloy and can lead to a considerable reduction In the fatigue resistance of the inducer and compressor wheels.

Chemical aids (i.e. solvents) are not necessary for cleaning during operation. The water injection method is based on the mechanical effect of impinging droplets of water. The water has to be injected with the turbocharger running at the highest possible speed. If solvents were to be used, the speed would have to be lower and the solvent injected for a longer time to have any effect.

Cleaning the compressor

The proposed cleaning method, carried out periodically, will prevent a thick layer of dirt from forming. A thick layer of dirt can cause a drop in efficiency and increased unbalance on the compressor side of the turbocharger, which could influence the lifetime of the bearings. The cleaning interval will depend on the environmental condition and on the installed air filter. The compressor wheel of the turbocharger can be cleaned during operation by spraying water into the air inlet casing. The dirt layer is removed by the impact of the injected water. Since the liquid does not act as a solvent there is no need to add chemicals. The use of salt-water is not allowed, as this would cause corrosion of the aluminium compressor wheel and the engine. Water is injected from a water vessel that holds the required quantity of water.

Water is injected before the compressor wheel via an injection pipe fitted in the filter silencer or the suction branch in order to clean the compressor stage in operation. The water does not act as a solvent in the process, but the deposit is removed by mechanical impact of the drops.

Blower side water washing

1. It can be done when M/E on full load.

2. Fill up the warm fresh water to hopper and closed the cover.

3. Open the valve and water will flow into the blower casing and mechanically attack the blower blades and clean the deposits.

4. Close the valve. Open the cover and check the cleaning water must be empty.

2.1 Wet cleaning of the compressor:-Only fresh water to be used without any cooling additives or solvents, which could lead to deposition in the flow ducts. In general, cleaning should be carried out every 24 to 72 operating hours. Cleaning of the compressor stage must be performed with the engine warm from running and as fully loaded as possible (i.e at turbocharger speed).

The success of cleaning can be seen from the scvanging pressure, if required cleaning can be repeated after a stabilisation period of atleast 10 minutes. Engine must be run loaded for atleast another 15 minutes after compressor cleaning.

The water should be injected during the engine is running warm at the highest possible load (above 75% load). For an effective cleaning, inject all the water required within a minute.

The specified water quantity should be observed, because entering uncontrolled water to turbocharger and engine causes a trouble. Either charged air pressure or exhaust gas temperature changes after injecting water. If pressure or temperature does not change, it may only be repeated after 10 minutes. If the parameters are not changing upon 3 times injection it can be concluded that the deposit is too hard or compressor wheel is damaged.

Procedure:

1. The best results are obtained by injecting water during full-load operation of the engine, i.e. when the turbocharger is running at full speed.

2. The complete contents of the water vessel should be injected within 4 to 10 seconds.

3. Successful cleaning is indicated by a change in the charge air or scavenging pressure, and in most cases by a drop in the exhaust gas temperature.

4. If cleaning has net produced the desired results, it can be repested after 10 minutes.

5. The interval between compressor cleanings will depend on the condition of the turbocharger suction air. It can vary from 1 to 3 days of operation.

If a very thick layer has built up and it cannot be removed using the method described, it will be necessary to dismantle the turbocharger in order to clean the compressor side.

Principle:

Since the dirt layer is removed by the kinetic energy of the water droplets, the engine has to be run at full load. (Being done from the manual)

1. It can be done when M/E on full load.

2. Fill up the warm fresh water to hopper and closed the cover.

3. Open the valve and water will flow into the blower casing and mechanically attack the blower blades and clean the deposits.

4. Close the valve. Open the cover and check the cleaning water must be empty.

2.1 Wet cleaning of the compressor:-Only fresh water to be used without any cooling additives or solvents, which could lead to deposition in the flow ducts. In general, cleaning should be carried out every 24 to 72 operating hours. Cleaning of the compressor stage must be performed with the engine warm from running and as fully loaded as possible (i.e at turbocharger speed).

The success of cleaning can be seen from the scvanging pressure, if required cleaning can be repeated after a stabilisation period of atleast 10 minutes. Engine must be run loaded for atleast another 15 minutes after compressor cleaning.

The water should be injected during the engine is running warm at the highest possible load (above 75% load). For an effective cleaning, inject all the water required within a minute.

The specified water quantity should be observed, because entering uncontrolled water to turbocharger and engine causes a trouble. Either charged air pressure or exhaust gas temperature changes after injecting water. If pressure or temperature does not change, it may only be repeated after 10 minutes. If the parameters are not changing upon 3 times injection it can be concluded that the deposit is too hard or compressor wheel is damaged.

Procedure:

1. The best results are obtained by injecting water during full-load operation of the engine, i.e. when the turbocharger is running at full speed.

2. The complete contents of the water vessel should be injected within 4 to 10 seconds.

3. Successful cleaning is indicated by a change in the charge air or scavenging pressure, and in most cases by a drop in the exhaust gas temperature.

4. If cleaning has net produced the desired results, it can be repested after 10 minutes.

5. The interval between compressor cleanings will depend on the condition of the turbocharger suction air. It can vary from 1 to 3 days of operation.

If a very thick layer has built up and it cannot be removed using the method described, it will be necessary to dismantle the turbocharger in order to clean the compressor side.

Principle:

Since the dirt layer is removed by the kinetic energy of the water droplets, the engine has to be run at full load. (Being done from the manual)

Operation instruction for Compressor cleaning:

1. Cleaning should be performed at high engine load and warm turbocharger

2. Open the filling cap(2) and fill the water container(1) with clean freshwater.

3. Close the filling cap(2) and open the valve(3) for approx.3 minutes.

4. Close the valve(3) and check, that all water has been sucked out.

5. Repeat steps 2-4.

6. In dirty operating conditions the cleaning procedure (steps 2-4) can be repeated once more, In total, up to 3 cleaning cycles are allowed.

7. After finishing the compressor cleaning procedure the engine should run at least 5 minutes at high load.

8. Compressor cleaning should be performed approx. every 24 operating hours.

Instruction for U-Tube manometer:

1. The U-tube manometer is used for monitoring of the filter ring condition.

2. For best readability lightly colored water should be filled into the U-tube.

3. Under new conditions the pressure loss is less than 120 mmH2O at full load.

4. The filter should be cleaned at the latest, when the pressure loss has reached 200mmH2O.

3. Cleaning turbine blades and nozzle ring in operation.

used and the quality of the combustion, such cleaning of the turbines will have to be carried out more or less frequently. For the turbine we recommend wet cleaning (water injection) as well as dry cleaning (granulate).

We continue to recommend wet cleaning for installations where the engine output can be reduced. The boost pressure has to be above 0.3 bar to prevent water entering the turbine end oil chamber and the exhaust gas temperature before turbine should not exceed 430 °C.

For further details please refer to our technical Information Sheets or to "Cleaning Even when cleaning is carried out regularly during operation, the rotor still has to be removed and cleaned according to a fixed schedule. From time it should be professionally rebalanced on a proper balancing machine to be sure that it run smoothly and that bearing loads are minimized. It is recommended that the compressor and turbine be cleaned with the turbocharger running. Periodic cleaning reduces or even prevents contamination, allowing significantly longer intervals between overhauls.

Some of the deposits have their origin in soot, molten ash, scale and unburned oil, partially burnt fuel and sodium vanadyl-vanadat. Investigations have shown that most of the residues are caused by the calcium in the lube oil reacting with the sulphur from the fuel to form calcium sulphate during the combustion process. The quantity of the deposits depends on the quality of the combustion, the fuel used, and the lube oil consumption. The frequency with which cleaning has to be carried out depends on the extent of the contamination on the turbine side.

With periodic cleaning during operation, the interval between overhauling can be extended.

The boost pressure has to be above 0.3 bar to prevent water entering the turbine end oil chamber.

The exhaust gas temperature before turbine should not exceed 430deg cel .

The drain of the gas outlet has to be opened to drain the non evaporated water.

The quantity of injected water will depend on the exhaust gas temperature, water pressure, size of the turbocharger and number of gas inlets.

The interval between turbine cleanings will depend on the combustion, the fuel used and the fuel oil consumption. It can vary from 1 to 20 days of operation.

Principle: The dirt layer on the turbine components is removed by thermal shock rather than the kinetic energy exerted by the water droplets.

Turbocharger Washing: The Turbocharger turbine and compressor sides must be cleaned regularly as per maker’s recommendations. The cleaning of the turbine and blower sides is carried out to remove carbon, soot, and other exhaust deposits.

Purpose of turbocharger water washing

a. To ensure efficient functioning of turbocharger.

b. To protect the compressor and turbine from contamination (Deposits).

Disadvantages of turbocharger water washing the turbine side

a. Engine speed has to lower.

b. Thermal stress and corrosion usually occurred.

c. Longer cleaning time.

d. Very fine hard deposits and residues cannot be removed easily with water washing.

1. Cleaning should be performed at high engine load and warm turbocharger

2. Open the filling cap(2) and fill the water container(1) with clean freshwater.

3. Close the filling cap(2) and open the valve(3) for approx.3 minutes.

4. Close the valve(3) and check, that all water has been sucked out.

5. Repeat steps 2-4.

6. In dirty operating conditions the cleaning procedure (steps 2-4) can be repeated once more, In total, up to 3 cleaning cycles are allowed.

7. After finishing the compressor cleaning procedure the engine should run at least 5 minutes at high load.

8. Compressor cleaning should be performed approx. every 24 operating hours.

Instruction for U-Tube manometer:

1. The U-tube manometer is used for monitoring of the filter ring condition.

2. For best readability lightly colored water should be filled into the U-tube.

3. Under new conditions the pressure loss is less than 120 mmH2O at full load.

4. The filter should be cleaned at the latest, when the pressure loss has reached 200mmH2O.

3. Cleaning turbine blades and nozzle ring in operation.

Turbine

When

heavy Fuel is used the nozzle vanes and turbine blades become dirty due

to combustion residue and, though to a far smaller extent, the

additives in the lubricating oil. Apart from a very thin coating of

additives, turbochargers operating on engines using diesel oil show no

signs of dirt deposits. When engines use heavy oil it is necessary to be

able to clean the turbines during operation. Depending on the

composition of the heavy fuelused and the quality of the combustion, such cleaning of the turbines will have to be carried out more or less frequently. For the turbine we recommend wet cleaning (water injection) as well as dry cleaning (granulate).

We continue to recommend wet cleaning for installations where the engine output can be reduced. The boost pressure has to be above 0.3 bar to prevent water entering the turbine end oil chamber and the exhaust gas temperature before turbine should not exceed 430 °C.

For further details please refer to our technical Information Sheets or to "Cleaning Even when cleaning is carried out regularly during operation, the rotor still has to be removed and cleaned according to a fixed schedule. From time it should be professionally rebalanced on a proper balancing machine to be sure that it run smoothly and that bearing loads are minimized. It is recommended that the compressor and turbine be cleaned with the turbocharger running. Periodic cleaning reduces or even prevents contamination, allowing significantly longer intervals between overhauls.

Cleaning the turbine

The combustion of heavy fuel

in diesel engines causes fouling of the turbine blades and nozzle ring.

The result of this foulıng is reduced turbine efficiency and engine

performance as well as an Increase In the exhaust gas temperature.

Experience has shown that the contamination on the turbine side can be

reduced by regular cleaning in operation, and that such cleaning allows

longer intervals between the turbocharger overhauls.Some of the deposits have their origin in soot, molten ash, scale and unburned oil, partially burnt fuel and sodium vanadyl-vanadat. Investigations have shown that most of the residues are caused by the calcium in the lube oil reacting with the sulphur from the fuel to form calcium sulphate during the combustion process. The quantity of the deposits depends on the quality of the combustion, the fuel used, and the lube oil consumption. The frequency with which cleaning has to be carried out depends on the extent of the contamination on the turbine side.

With periodic cleaning during operation, the interval between overhauling can be extended.

Turbocharger cleaning and washing

Procedure for wet cleaning (2- and 4-stroke):The boost pressure has to be above 0.3 bar to prevent water entering the turbine end oil chamber.

The exhaust gas temperature before turbine should not exceed 430deg cel .

The drain of the gas outlet has to be opened to drain the non evaporated water.

The quantity of injected water will depend on the exhaust gas temperature, water pressure, size of the turbocharger and number of gas inlets.

The interval between turbine cleanings will depend on the combustion, the fuel used and the fuel oil consumption. It can vary from 1 to 20 days of operation.

Principle: The dirt layer on the turbine components is removed by thermal shock rather than the kinetic energy exerted by the water droplets.

Turbocharger Washing: The Turbocharger turbine and compressor sides must be cleaned regularly as per maker’s recommendations. The cleaning of the turbine and blower sides is carried out to remove carbon, soot, and other exhaust deposits.

Purpose of turbocharger water washing

a. To ensure efficient functioning of turbocharger.

b. To protect the compressor and turbine from contamination (Deposits).

Disadvantages of turbocharger water washing the turbine side

a. Engine speed has to lower.

b. Thermal stress and corrosion usually occurred.

c. Longer cleaning time.

d. Very fine hard deposits and residues cannot be removed easily with water washing.

3.1 Wet cleaning:-

To clean the turbine components during operation, the thermal shock principle is applied in combination with a subsequent flushing phase. To achieve the required thermal shock effect for wet cleaning, the temperature before the turbine must lie between 400 & 450 deg cel., to achieve the optimum thermal shock. During the cleaning process, the layer of dirt on the material surface of the turbine components loosens. Only fresh water without any cleaning agent or solvent to be used.

The volume of water and duration of injection must be observed carefully, low volume causes inadequate cleaning and high volume leads to impermissible thermal stresses.

In case of multiple turbocharger the cleaning of all turbocharger at the same time causes a great drop in performance. The engine must be running for further 10 minutes after the cleaning is completed.

The frequency of cleaning is approx. 200 service hours.

The absolute static water pressure before the water connection on the turbine casing must be at least 1.5 bar above the absolute turbine inlet pressure.

Turbine side water washing procedure

1. Turbine side water washing can be made with hot fresh water.

2. Inform to the bridge

3. Reduce the M/E rpm to recommended speed and hence turbocharger rpm.

4. Check the water washing injection nozzle if fitted. (Directly aim to the exhaust grips before entering to the turbocharger)

5. Open turbocharger drain valve.

6. Open the water supply about 1 bar to turbine side.

7. Water washing must be made until the clean water comes out.

8. Close the water supply and remove the nozzle.

9. Exhaust side drain can be closed after all water is drained out and dried.

10. Inform to the bridge and increase the M/E rpm gradually to sea speed.

11. The turbine side water washing is usually at departure after manoeuvring time.

12. For usual practice cleaning is done at every 500 hrs, running hour depending on the cleanlıness of the turbocharger.

Wet cleaning procedure:-

To clean the turbine components during operation, the thermal shock principle is applied in combination with a subsequent flushing phase. To achieve the required thermal shock effect for wet cleaning, the temperature before the turbine must lie between 400 & 450 deg cel., to achieve the optimum thermal shock. During the cleaning process, the layer of dirt on the material surface of the turbine components loosens. Only fresh water without any cleaning agent or solvent to be used.

The volume of water and duration of injection must be observed carefully, low volume causes inadequate cleaning and high volume leads to impermissible thermal stresses.

In case of multiple turbocharger the cleaning of all turbocharger at the same time causes a great drop in performance. The engine must be running for further 10 minutes after the cleaning is completed.

The frequency of cleaning is approx. 200 service hours.

The absolute static water pressure before the water connection on the turbine casing must be at least 1.5 bar above the absolute turbine inlet pressure.

Turbine side water washing procedure

1. Turbine side water washing can be made with hot fresh water.

2. Inform to the bridge

3. Reduce the M/E rpm to recommended speed and hence turbocharger rpm.

4. Check the water washing injection nozzle if fitted. (Directly aim to the exhaust grips before entering to the turbocharger)

5. Open turbocharger drain valve.

6. Open the water supply about 1 bar to turbine side.

7. Water washing must be made until the clean water comes out.

8. Close the water supply and remove the nozzle.

9. Exhaust side drain can be closed after all water is drained out and dried.

10. Inform to the bridge and increase the M/E rpm gradually to sea speed.

11. The turbine side water washing is usually at departure after manoeuvring time.

12. For usual practice cleaning is done at every 500 hrs, running hour depending on the cleanlıness of the turbocharger.

Wet cleaning procedure:-

1.

Adjust the engine load until scavenging air pressure is in the range of

0.3 to 0.6 bar (gauge pressure). The exhaust-gas temperature before

turbocharger has to be below 430 deg cel. and the auxiliary blower must

be in operation.

2. Open the drain hole (valve F, 1-3:close, 1-2:open) of the gas outlet casing and check whether exhaust gas emerges.

3. Close the drain valve B.

4. Open the valve C.

5. Open valve D slowly until the pressure gauge E indicates 0.2-0.25 bar.

6. Inject water for 5 minutes while keeping the engine load constant.

7. Close valve D.

8. Open drain valve B for drain during 5 minutes.

9. Close valves B and C

10. Close the drain hole(valve F, 1-3:open, 1-2:close) of the gas outlet casing.

a. the engine should be operated at least for further 10 minutes to prevent corrosion of the turbocharger parts on turbine-end.

b. depending on the load only little or no water flows out the drain hole F. water drain is not relevant for the cleaning effect. water injection can be confirmed with reduced t/c speed and lower exhaust gas temperature after t/c during cleaning.

c. if more than one t/c is mounted it recommended to clean one after the other.

2. Open the drain hole (valve F, 1-3:close, 1-2:open) of the gas outlet casing and check whether exhaust gas emerges.

3. Close the drain valve B.

4. Open the valve C.

5. Open valve D slowly until the pressure gauge E indicates 0.2-0.25 bar.

6. Inject water for 5 minutes while keeping the engine load constant.

7. Close valve D.

8. Open drain valve B for drain during 5 minutes.

9. Close valves B and C

10. Close the drain hole(valve F, 1-3:open, 1-2:close) of the gas outlet casing.

a. the engine should be operated at least for further 10 minutes to prevent corrosion of the turbocharger parts on turbine-end.

b. depending on the load only little or no water flows out the drain hole F. water drain is not relevant for the cleaning effect. water injection can be confirmed with reduced t/c speed and lower exhaust gas temperature after t/c during cleaning.

c. if more than one t/c is mounted it recommended to clean one after the other.

3.2 Grit cleaning of turbine:-

There is no need to

reduce load as thermal shocking is not a case in grit washing, generally

it is carried out at high load. Carbon granules or walnut shells are

used for this. The frequency of this cleaning is of 24hrs.

Pressurized air is used to push the grits inside the turbine before the nozzle ring.

Grit Washing or Dry Cleaning of Turbocharger

1. Turbine side cleaning is superseded by walnut shell, with grain size of 12 to 34 mesh

2. No speed reduction required and cleaning can be done at full speed, once every day

3. Compressed air of (3 -5 bar) is used to help the grains strike the deposited Turbine Blades and Nozzles, giving effective cleaning of hard particles

4. Air supply pipe is fitted to solid grain container, and grains are injected into exhaust system by air pressure, at the same point (as in water washing) just after exhaust grids

5. Turbine casing drain kept open during cleaning time (about 2 minutes only).

Pressurized air is used to push the grits inside the turbine before the nozzle ring.

Grit Washing or Dry Cleaning of Turbocharger

1. Turbine side cleaning is superseded by walnut shell, with grain size of 12 to 34 mesh

2. No speed reduction required and cleaning can be done at full speed, once every day

3. Compressed air of (3 -5 bar) is used to help the grains strike the deposited Turbine Blades and Nozzles, giving effective cleaning of hard particles

4. Air supply pipe is fitted to solid grain container, and grains are injected into exhaust system by air pressure, at the same point (as in water washing) just after exhaust grids

5. Turbine casing drain kept open during cleaning time (about 2 minutes only).

Advantages of solid (crystal) cleaning or grit washing

a. Not required to reduce engine rpm, thus not effect on scheduled voyage

b. No use of water, so no corrosion and thermal stress.

c. Cleaning time is short.

d. Do not wear turbine blade.

e. Effectively remove combustion residues and hard particle

Procedure for dry cleaning (2-stroke only):

The exhaust gas temperature before the turbine should not exceed .

The boost pressure has to be above 0.5 bar.

Dry cleaning has to be carried out more often than water cleaning as it is only possible to remove thin layers of deposits. A cleaning interval of 1 to 2 days is recommended.

To ensure effective mechanical cleaning, granulated dry cleaning media are best injected into the turbine at a high turbo-charger speed.

The quantity needed will vary from 0.2 l to 3l, depending on the size of the turbocharger.

Experience has shown that the best results are achieved with crushed nutshell or granulate.

Principle:

The layer of deposits on the turbine components is removed by the kinetic energy of the granulate causing it to act as an abrasive.

Devices for both methods are usually supplied by the engine builder and are manufactured in accordance with our recommendations. Experience has shown a combination of the two to be very effective in some cases.

Periodical dry cleaning is the most effective and economical method of cleaning turbocharger turbines on two-stroke engines. Providing the recommended material (e. g. nut shells), and also original spare parts, are always use.

b. No use of water, so no corrosion and thermal stress.

c. Cleaning time is short.

d. Do not wear turbine blade.

e. Effectively remove combustion residues and hard particle

Procedure for dry cleaning (2-stroke only):

The exhaust gas temperature before the turbine should not exceed .

The boost pressure has to be above 0.5 bar.

Dry cleaning has to be carried out more often than water cleaning as it is only possible to remove thin layers of deposits. A cleaning interval of 1 to 2 days is recommended.

To ensure effective mechanical cleaning, granulated dry cleaning media are best injected into the turbine at a high turbo-charger speed.

The quantity needed will vary from 0.2 l to 3l, depending on the size of the turbocharger.

Experience has shown that the best results are achieved with crushed nutshell or granulate.

Principle:

The layer of deposits on the turbine components is removed by the kinetic energy of the granulate causing it to act as an abrasive.

Devices for both methods are usually supplied by the engine builder and are manufactured in accordance with our recommendations. Experience has shown a combination of the two to be very effective in some cases.

Periodical dry cleaning is the most effective and economical method of cleaning turbocharger turbines on two-stroke engines. Providing the recommended material (e. g. nut shells), and also original spare parts, are always use.

Comments

Post a Comment