Answer MET Question 51

Question: With reference to Marine Electrical Circuits: A. Explain three methods of over current protection for electrical circuit. B. Explain with aid of diagram, the meaning of the term inverse current time characteristic.

Answer: A Three Methods of over current protection:

Motor

protection Protection of motors is required mainly to prevent

overheating which can cause deterioration of winding insulation and

burnout, if severe. Overheating as the result of overload, stalling,

single-phasing or prolonged starting period can be detected by a rise in

line current and by temperature change. Overheating as the result of

high ambient temperature or poor cooling due to blocked air passages can

only be detected by temperature rise within the windings.

Overload protection is required for all motors of more than 0.5 kW although different rules apply to steering gear motors and others essential to safety or propulsion. A conventional electromagnetic overload trip must have a time delay dashpot (similar to those for d.c. switchboards) to allow for high starting current in direct on-line started induction motors. Unfortunately, an electromagnetic overload trip can be reset quickly and a motor restarted repeatedly with the result of excessively high winding temperature, unless a temperature trip is also provided.

Overload protection is required for all motors of more than 0.5 kW although different rules apply to steering gear motors and others essential to safety or propulsion. A conventional electromagnetic overload trip must have a time delay dashpot (similar to those for d.c. switchboards) to allow for high starting current in direct on-line started induction motors. Unfortunately, an electromagnetic overload trip can be reset quickly and a motor restarted repeatedly with the result of excessively high winding temperature, unless a temperature trip is also provided.

Each of the three supply phases of the motor is fitted with an overload relay. Such an arrangement should detect single-phasing, where the symptoms are of high current in two supply lines only as well as straight overload. Operation of any of the relays will close the circuit to energise the time-delayed trip.

The thermistor is a thermal device which can be used in conjunction with an electromagnetic overload trip. One of these inserted in each of the three windings would detect overheating from any cause. Therrnistors are available with either a positive or a negative characteristic. The former type are more definite in operation because there is a very sharp rise in resistance at a particular temperature (as opposed to gradual drop in resistance of the other sort). Positive thermistors can be connected simply in series and the very small current which passes through them normally is cut off by the effect of overheating in any one of them. Cessation of the minute checking current is used as the signal to operate the motor trip. Alternative methods of detecting overload current employ directly or indirectly heated hi-metal strips. Excessive current in any of the supply cables will cause deflection of the bi-metal strip through temperature rise. Thickness of the strips is used to delay tripping when a motor starts. (A thick bi-metal strip takes longer to heat.) Short-circuit protection is also a requirement for motors of over 0.5 kW. Fuses of the cartridge/high rupture capacity (HRC) design are employed to provide the necessary rapid interruption of high fault current. Because short-circuit current may be high enough to damage normal motor contacts, the fuses may be arranged to break first in the event of short circuit. The secondary function of fuses is to provide back-up for the other protective devices.

Protecting an electric motor basically involves preventing the motor from getting too hot. Remember, every 10 deg. C. above the maximum recommended temperature of the insulation can reduce its working life by half. If the temperature exceeds the maximum set value for the motor insulation its contactor is tripped to stop the motor and allow it to cool down.

Three main types of direct temperature sensors can be used. These are Thermocouple, Resistance temperature device (RTD) and Thermistor.

The thermistor sensor is probably the most common as its thermal characteristic more closely matches that of a motor than the other types. Thermistors are small pellets of semiconductor materials which are embedded into the insulation of all three motor stator windings during manufacture. When a thermistor gets hot its resistance changes dramatically. They are connected so that if the motor

temperature gets too high the starter contactor will be tripped by an electronic protection relay to stop the motor.

Direct thermistor protection is usually only fitted to large motors, e.g. bow thrusters, FD fans, air conditioning compressors, etc.

Most motors are protected by monitoring the temperature indirectly by measuring the current flowing in the supply lines.

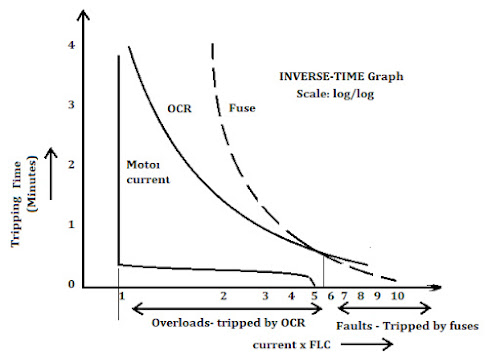

This method uses electronic, thermal or electromagnetic time-delayed overcurrent relays (OCRs) in the motor starter. The system is designed so that if the motor takes too much current because it is mechanically overloaded, the OCR will trip out the contactor coil, after a pre-set time delay, before severe overheating can occur. The largest overcurrent possible is the current taken when the motor has stalled.

This, of course, is the starting current of the motor which will be about five times the full load current. The contactor is capable of tripping this stalled current quickly and safely.

lf a short-circuit occurs in the motor, the starter, or the supply cable, then a huge fault current will flow. If the contactor tries to open under short-circuit conditions, serious arcing will occur at its contacts such that it may fail to interrupt the fault current. The prolonged short-circuit current will cause serious damage to the motor, starter and cable with the attendant risk of an electrical fire. To prevent this, a set of fuses or a circuit breaker is fitted upstream of the contactor which will trip out almost instantaneously thereby protecting the contactor during a short-circuit fault.

It is important that the tripping characteristics, of the OCR and fuses/circuit breaker are co-ordinated so that the contactor trips on thermal overcurrent while the fuses/circuit breaker interrupt shortcircuit fault currents. This contactor + fuse arrangement is usually called back-up protection.To protect a modern CMR (Continuous Maximum Rating) motor the thermal OCR should be set at the full-load current (FLC) rating of the motor. The motor fuses are not chosen for their rated current but for their inverse current/time (I/t) characteristic. This means that the current rating of fuses used to protect a motor does not appear to have any direct relationship to the FLC rating of the motor.

Fuses used for back-up protection for motor circuits have a special time/current characteristic. They are generally carrying steady currents well below their rated capacity to allow for short duration DOL starting currents without blowing.

Consequently they do not protect against normal overloads but do protect the motor and supply system against a short-circuit fault. Fuses designed for motor circuit back-up protection have a restricted continuous current rating (called "M" rating) as compared with their fusing characteristic.

Hence a typical fuse designation for motor circuits could be "32M63" which indicates a continuous rating of 32 A but a rating of 63 A for the starting period.

Comments

Post a Comment